Limestone Manufacture Process

How Lime is Made

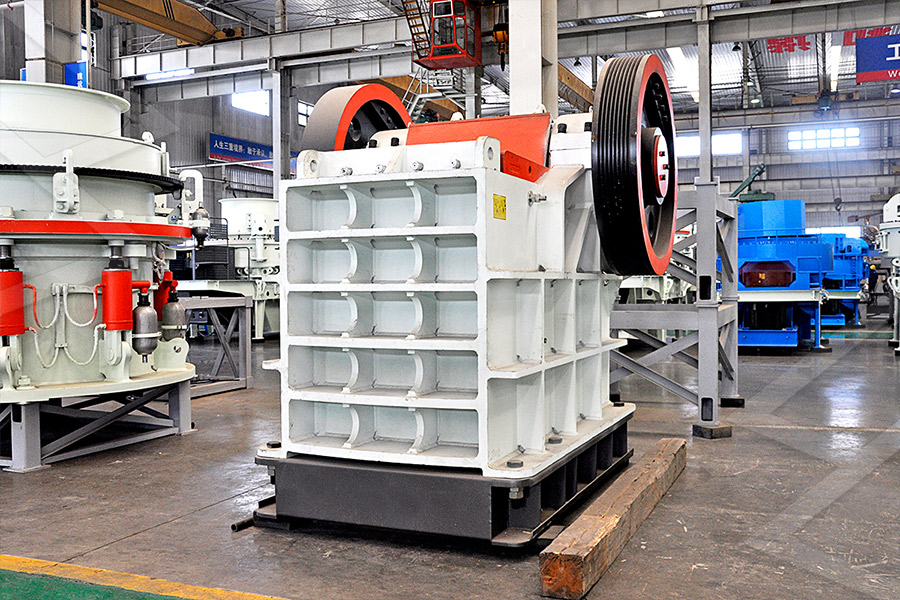

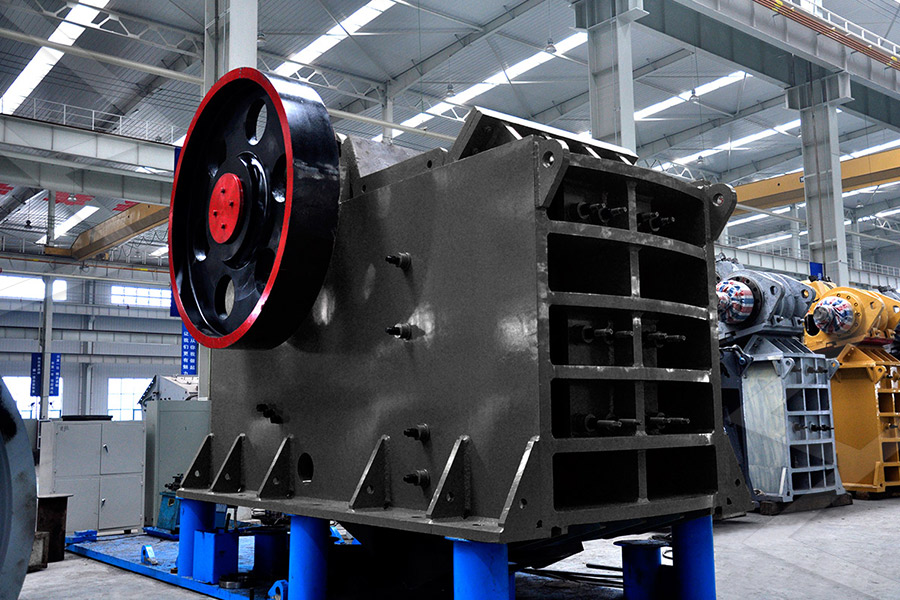

Lime production begins by extracting limestone from quarries and mines Sizing Limestone enters a primary crusher to break the rock Depending on the size of the feedstone required, limestone may go through a secondary or tertiary crusher to further reduce its size2015年9月10日 processes in the production of lime are: (1) quarrying raw limestone; (2) preparing limestone for the kilns by crushing and sizing; (3) calcining limestone; (4) processing 1117 Lime Manufacturing US EPA2018年9月15日 The leading stone produced in the US, limestone accounts for 42% of total domestic production It is quarried in nine states with Wisconsin and Indiana producing over Limestone Quarrying and Processing: A LifeCycle 2021年3月3日 Processing of limestone into lime is tightly controlled to assure quality products Figure 77 (EuLA 2014) shows the overall manufacturing process The four main production Lime SpringerLink

.jpg)

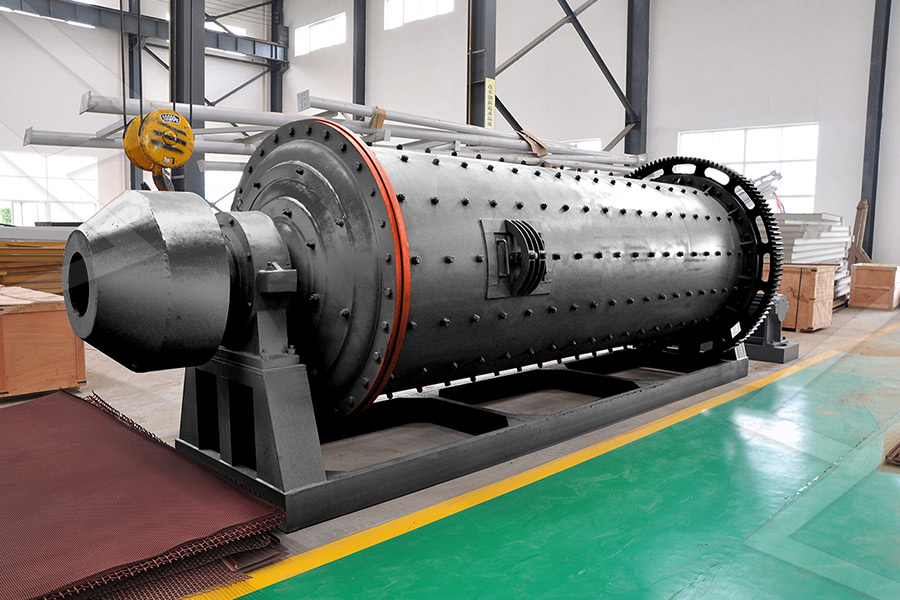

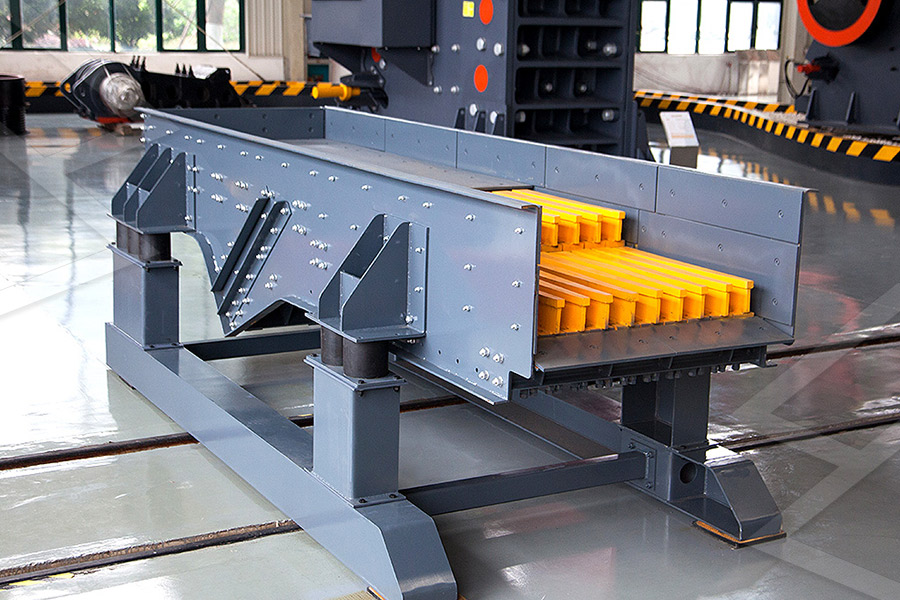

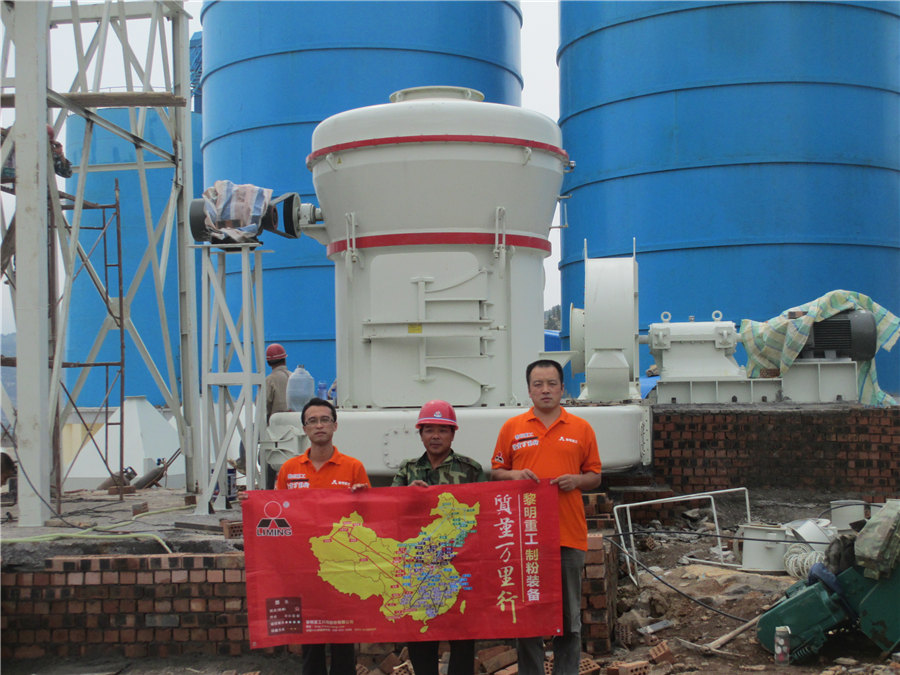

Lime Production Process and Required Equipment

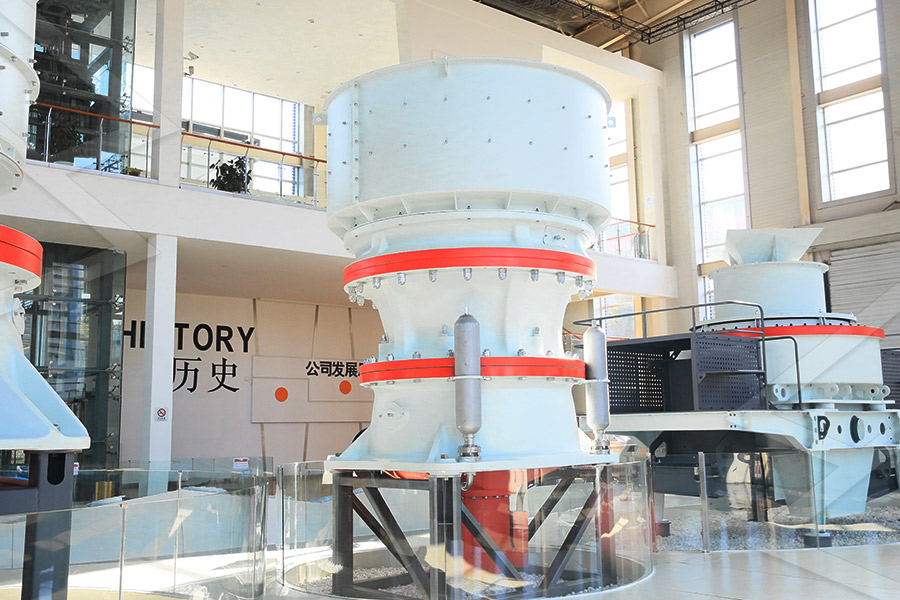

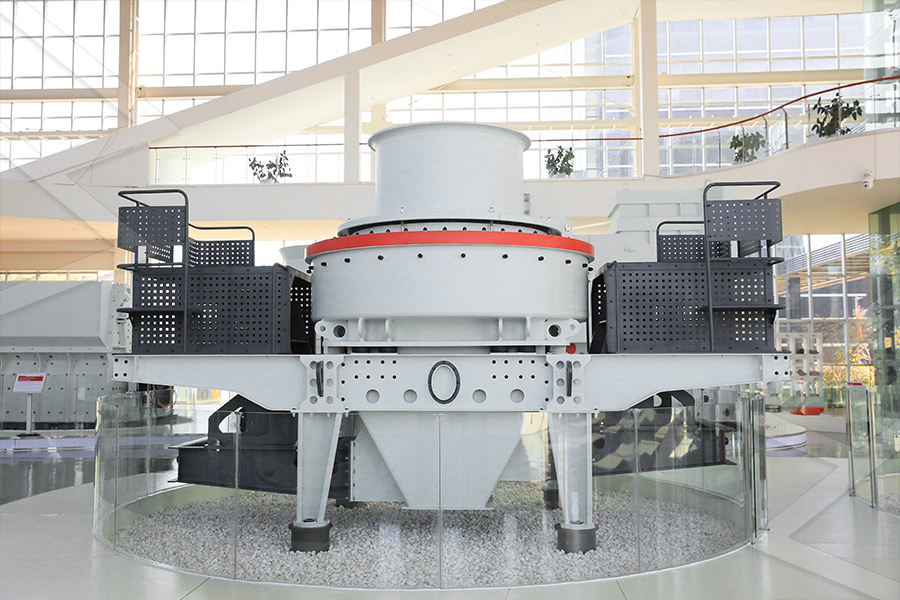

2023年2月15日 How is lime produced by limestone? Lime is made of limestone which needs to be calcinated with a temperature over 900℃ Limestone is a kind of sedimentary rock that is alkaline, and the main component is calcium 2024年10月30日 When the rock is heated in a specially designed kiln to over 900°C, a chemical reaction occurs and creates calcium oxide, otherwise known as lime Learn more on each of Production European Lime AssociationThe lime production process is energy intensive and results in CO 2 emissions from both mineralogical transformation process and energy used The production of one tonne of lime Lime Production an overview ScienceDirect Topics2023年4月26日 Two general phases of limestone production exist: quarrying and processingA LifeCycle Inventory of Limestone Dimension Stone

Lime and Limestone: Chemistry and Technology, Production

1998年7月8日 Processing and Dispatch of Limestone Sampling and Testing of Limestone USES AND SPECIFICATIONS OF LIMESTONE Overview and Economic Aspects of the The production of lime (quicklime, CaO) is an energyintensive process The starting material is limestone, which is found frequently all over the worldProduction from stone to lime Maerz Ofenbau AG2023年10月21日 Cement Production: Limestone is a key ingredient in the production of cement It is ground into a fine powder and mixed with clay and other materials to create cement, which is essential in the construction industry Formation Process of Limestone Limestone is a sedimentary rock that forms through a complex process that involves the Limestone Types, Properties, Composition, Formation, Uses2024年5月13日 The steel production process is a multifaceted journey that begins with extracting and processing iron ore, a primary raw material essential to steel making Limestone, introduced during the steelmaking process, Steel Manufacturing: Process, Types, and

.jpg)

Cement Production Demystified: StepbyStep Process and

2024年1月18日 1 Cement production process overview What are the different steps to manufacture cement ? The production process of cement is not very complex but has many steps to be able to go from raw limestock rocks to a quality cement The steps are the following [Britannica] : Limestone rocks production in a quarry2019年10月23日 The crushed limestone and aggregates such as sand, clay and ironstone are blended together in a raw mill to a particle size of 90 micrometres, producing “kiln feed” Cement Plant: The Manufacturing Process worldcementassociation 1 Limestone (CaCO3) is taken from a quarry 2 4 3 The limestone is fed into a crusher and then stored until neededCement Plant: The Manufacturing Process 4 5 World 1998年7月8日 PRODUCTION OF LIMESTONE Formation, Classification and Occurrence of Limestone Physical and Chemical Properties of Limestone Prospecting and Quarrying Processing and Dispatch of Limestone Sampling and Testing of Limestone USES AND SPECIFICATIONS OF LIMESTONE Overview and Economic Aspects of the Limestone Lime and Limestone: Chemistry and Technology, Production 2023年2月15日 Grain size of limestone 1 In the process of calcination, the granularity of the raw limestone affects the whole process a lot Since the separation of CO2 proceeds slowly from the surface of the limestone to the inside, the calcination of large particle size is more difficult than that of small ones, and it takes a longer timeLime Production Process and Required Equipment

Cement Extraction, Processing, Manufacturing Britannica

2024年9月26日 Cement Extraction, Processing, Manufacturing: Raw materials employed in the manufacture of cement are extracted by quarrying in the case of hard rocks such as limestones, slates, and some shales, with the aid of blasting when necessary Some deposits are mined by underground methods Softer rocks such as chalk and clay can be dug directly by excavators 2023年7月3日 To manufacture steel, various raw materials are required The primary ingredients include iron ore, coal, and limestone Iron ore is the main source of iron, coal acts as a fuel in the manufacturing process, and limestone is used as a fluxing agent to remove impuritiesHow is Steel Manufactured: A Comprehensive Guide to the The lime cycle shows the stages from quarrying the limestone through to the production of mortars and plasters for our buildings and how it slowly, through the reabsorption of Carbon Dioxide, reverts to its original chemical form (Calcium Carbonate) in the wall This process is called carbonation The ‘set’ or carbonation must occur Lime and its Production2018年8月28日 CEMENT MANUFACTURING PROCESS PHASE II: PROPORTIONING, BLENDING GRINDING Generally, limestone is 80% and remaining 20% is the clay Proportioning of raw material at cement plant laboratory Now cement plant grind the raw mix with the help of heavy wheel type rollers and rotating table Rotating table rotates continuously Cement Manufacturing Process The Engineering Community

.jpg)

Manufacturing, Classification and Storage Civil Engineering

2021年1月15日 Manufacturing of Lime The raw material for the manufacturing of Lime is Limestone (CaCO 3) Lime is obtained from limestone through a process known as calcination Other raw materials from which Lime can be manufactured are kankars, shell, corals and chalk2021年2月9日 1 Collection of raw materials The raw materials such as silica (in the form of sand or quartz SiO2), soda ash (Na3CO3), limestone (CaCO3), and cullet (broken glass) are collected separately and mixed in a proper proportion The fusion of cullet (broken glass) is added to bring down the melting point of the chargeManufacture of Glass: Step by Step Process Sciencedoze2019年8月26日 The early manufacturing process of cement was through wet process, in which slurry, made of ground raw material and water, used to feed the rotary kiln The major raw materials used as a source of CaO for cement manufacturing are limestone, chalk, marl, etc These raw materials by virtue of their natural occurrence contains other mineral Chapter 4 Cement Manufacturing and Process Control2018年7月3日 LC 3 consists primarily of CC and limestone, where limestone helps in the production of carbonate ions (CO 2− 3 ), which combine with alumina present in the CC to form carboaluminate phases Industrial Production of Limestone Calcined Clay Cement (LC

.jpg)

Cement Manufacturing Process: Know Extraction, Processing

The major raw materials used in Cement Manufacturing Process include: Limestone is the main component and acts as a source of calcium It is abundant and found in large deposits around the world Limestone provides the necessary calcium oxide (lime) that reacts with other materials during the Cement manufacturing process 2024年3月13日 It also helps in the removal of impurities and enhances the overall efficiency of the production process About 95% of limestone is used by the cement industry, 3% by the Iron and steel industry, and 1% each by the chemical other remaining industries The consumption pattern of limestone in various industries in the country is depicted in Fig 1:Limestone—A Review with Special Reference to the Iron and Even though equipment is improved and higher production rates can be achieved, the processes inside the blast furnace remain the same The blast furnace uses coke, iron ore and limestone to produce pig iron Coal traditionally has been a key part of the cokemaking processSteel Production American Iron and Steel Institute2024年5月22日 The cement production process 1 The Quarry: The cement production process begins with the extraction of limestone and clay from the quarry 2 Crusher and PreBlending: The material is then crushed to reduce particle sizes and blended to reduce variability in composition 3 Raw Mill and Kiln: Raw materials and additives areA practical guide to improving cement manufacturing

.jpg)

Cement Manufacturing—Technology, Practice, and

2021年11月16日 76 4 Cement Manufacturing—Technology, Practice, and Development Fig 42 Modern dry process cement production process 424 Manufacturing of Cement Clinker The prepared raw material is called the “kiln feed” and is fed to the kiln In the kiln, this kiln feed is subjected to a thermal treatment process which consists ofLimestone is the main raw material for processing RBPC, which facilitates its global scaleup potential RBPC cement can be manufactured in conventional OPC production facilities with minor modifications to the raw mix design and fuel requirements For instance, China has started manufacturing RBPC using dryprocess rotary kilns with preheatersClinker Production an overview ScienceDirect TopicsEach process is explained chemical reactions for manufacture of Portland Cement Cement is a greenish grey colored powder, made of calcined mixtures of clay and limestone When mixed with water becomes a hard and strong Manufacture of Cement Materials and 2021年7月15日 It may be noted that the cement manufacturing process is resource and energy intensive due to the extreme heat required Depending on the type and process, a cement plant requires 60–130 kg of fuel oil and 110 kWh of electricity to produce one tonne of cement In this way, the total cost of limestone production per ton would drop to Rs Limestone Mining, Industry, and Society SpringerLink

2 Major Roles of Limestone in Cement Manufacturing

2023年5月27日 Limestone plays two major roles in the cement manufacturing process, one is used as a raw material for cement clinker, and the other is used as a cement admixture Limestone is one of the key raw materials of cement clinker Around 8090% of the raw material for the kiln feed is limestone2021年11月17日 During the twentieth century, cement manufacture spread worldwide By 2019, India and China have become the world leaders in cement production, followed by Vietnam, the United States, and Egypt The primary cement manufacturing process involves the mining of raw materials, mainly limestone and clay, which are used in cement manufacturingCement Manufacturing—Technology, Practice, and 2021年2月16日 replaced the older glass manufacturing methods and transformed glass production around the world Today, the vast majority of flat glass utilized is manufactured by the float glass process Making float glass begins with a mixture of the raw materials based on approximately 50% silica sand, soda ash, limestone, rouge and dolomiteManufacturing Process for Float Glass Guardian GlassThe primary raw materials in glass are sand, soda, limestone, clarifying agents, coloring and glistening glass Glass sand is about ¾th of the entire glass composition precision in composition and strict adherence to high quality standards in the manufacturing process The company has a dedicated sand beneficiation plant in Tada where Glass Manufacturing Process How is Glass made Saint

THE STORY OF CEMENT MANUFACTURE CEMBUREAU

2021年11月24日 Cement manufacture The cementmaking process can be divided into two basic steps: • Clinker (the main constituent of cement) is first made in a kiln with gas up to 2000°C, which heats raw materials such as limestone (calcium carbonate) with small quantities of other materials (eg, clay) to 1450°C During this process, known as 2024年10月22日 Stage of Cement Manufacture There are six main stages of the cement manufacturing process Stage 1: Raw Material Extraction/Quarry The raw cement ingredients needed for cement production are limestone (calcium), sand and clay (silicon, aluminum, iron), shale, fly ash, mill scale, and bauxite The ore rocks are quarried and crushed into smaller How Cement is Made Cement Manufacturing Process2015年9月1日 21 PRODUCTION PROCESS, INPUTS, AND OUTPUTS The production of lime begins with the quarrying and crushing of limestone Limestone is a general term that covers numerous varieties of sedimentary rock Limestone can be composed of the following four minerals, plus impurities: calcite (CaCO 3), aragonite (also CaCO 3Lime Production: Industry Profile US EPA3 天之前 As a leading expert in the manufacture and use of lime and limestone products, Carmeuse is well positioned to be your partner to supply and optimize the use of limestone in your glassmaking process At our plants, we produce the consistency of material that you need, while our distribution network ensures a reliable supplyLimestone in Glassmaking: What You Need to Know

.jpg)

(PDF) Environmental Hazards of Limestone Mining and

2020年2月18日 The limestone mined is used chiefly for the manufacturing of cement, lime and edible lime etc Scientific studies revealed that loss of forest cover, pollution of water, soil and air, depletion of 2017年3月20日 The furnace used must be adapted to continuous operation and the production of a large tonnage By the process it should be possible to produce pig steel at a greater profit than by existing methods A series in which both limestone and coke were varied in the charge Group II A series in which the amount of coke in the charge was varied Pig Iron Manufacturing Process 911Metallurgist2007年4月1日 This process and parameters of fabricating light calcium carbonate from limestone were discussed in the paper Raw limestone in experiment comes from Luquan city, Hebei province The results of chemistry and XRD analysis indicate that ingredient of this limestone is mainly calcium carbonate, dolomite, silicon dioxide, which takes 8381%, 1103% Manufacture Process of Light Calcium Carbonate from LimestoneThe crushed raw materials are then delivered by beltconveyor to our production facilities, where we manufacture cement through a closely controlled chemical process In this process the limestone and clay are first prehomogenized, a process that consists of combining different types of limestone and clayProduction Process CEMEX Philippines

Understanding The Process of Limestone Lumps ZME

2024年9月26日 Steel Production: Limestone lumps are used in the steelmaking process to remove impurities and control the chemical composition of the steel Flue Gas Desulfurization : Power plants use lumps in flue gas desulfurization to reduce sulfur dioxide emissions, thereby helping in environmental conservationThis process and parameters of fabricating light calcium carbonate from limestone were discussed in the paper Raw limestone in experiment comes from Luquan city, Hebei province The results of chemistry and XRD analysis indicate that ingredient of this limestone is mainly calcium carbonate, dolomite, silicon dioxide, which takes 8381%, 1103% and 167% Manufacture Process of Light Calcium Carbonate from LimestoneRandom screened limestone is still used for traditional dry stone walling builders The highest grade is monumental stone This is a very uniform limestone with few surface imperfections These properties make it ideal for carving and limestone of this class can hold very fine detail when used in sculpture, headstones, plaques, or ornamental The Processing and Major Uses of Limestone AcademiaTo strengthen glass, manufacturers can use thermal tempering to heat and cool it rapidly Glass can also be strengthened chemically through an ion exchange process that makes the surface of the glass tougher soda, and limestone is heated, it can How Glass is Made What is Glass Made of? Corning

Precipitated Calcium Carbonate Carmeuse

4 天之前 The precipitated calcium carbonate production process consists of decarbonating limestone, which separates the CaO (calcium oxide) and CO 2 (carbon dioxide) Precipitated calcium carbonate is produced by slaking highcalcium quicklime to create a calcium hydroxide lime slurry, (Ca(OH) 2 ), that is then combined with captured carbon dioxide (CO 2 )2024年10月22日 Cement Clinker Manufacturing Process with Reactions Syeda Tahsin Hasan Extraction and Preparation of Raw Materials The main raw materials (limestone, clay chalk or basalt) are quarried from natural rocks They are crushed and transferred to preblending storage where other substances (such as sand, iron ore, bauxite, shale, slag, fly ash) are Cement Clinker Manufacturing Process with Reactions