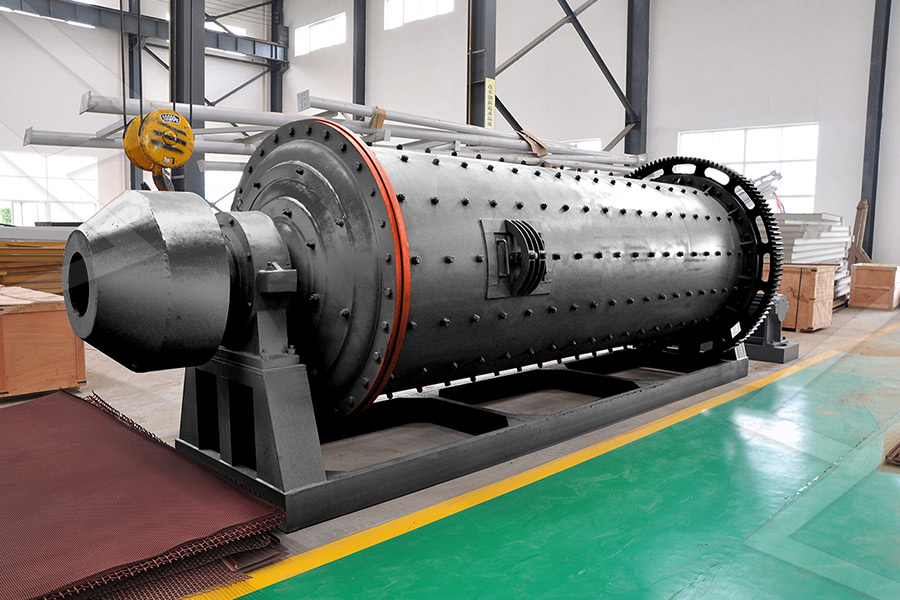

Contineus Ball Mill

.jpg)

Ball Mill an overview ScienceDirect Topics

The ball mill contains a hollow cylindrical shell that rotates about its axis This cylinder is filled with balls that are made of stainless steel or rubber to the material contained in it Ball mills are Reactive ball milling Reactive ball milling method is to mill starting materials under Ball Milling2022年11月1日 Performing controlled, scientific experiments on the impact of process and design parameters on product particle size distribution (PSD) in fullscale continuous ball Impact of ball size distribution, compartment configuration, The continuous ball mill is a ball grinding mill that can realize both wet grinding and dry grinding for 24 hours without any downtime AGICO, as a continuous ball mill manufacturer, offers high CONTINUOUS BALL MILL

A comparative study on a newly designed ball mill and the

2020年1月1日 In continuous wet ball mills, the composition of feed (hard ore or soft ore) to the mill varies continuously, leading to uncontrolled grinding in the mill In view of this, a new 连续式球磨机是具有更加的节能,更强的物料适应能力的一种机器。 我们知道 球磨机 在运行时的灵活性很高,因此,我们通过改变球磨机设备的布置来优化我们的生产,来简单化我们的生 连续式球磨机 百度百科Continuous ball mills provide a seamless and uninterrupted process for feeding, grinding, and discharging materials, offering versatility in both dry and wet grinding operationsContinuous Ball Mill Continuous Ball Mill Manufacturer2024年4月16日 XMQL φ 420×450 (900) grate continuous ball mill classifier is φ 150×1200 (1600) double screw conveyor, in order to match with φ 420×450 (900) specification cylinder XMQL Φ420×900 ZJH minerals

Comparison of Production Performance Between Continuous Ball Mill

According to different working principles, mineral ball mills can be divided into continuous ball mills and intermittent ball mills In addition to the differences in the working principle, what are The Continuous Ball Mill is a type of grinder used to grind and blend materials It works on the principle of impact and attrition The Continue Ball Mill is divided in three main components Continuous Ball Mill Laarmann Group BVBall Mills, Pebble Mills, Material Processing Mills: For more than a century, Patterson has been the industry leading manufacturer of wet and dry grinding mills for size reduction or dispersal Patterson’s ball, pebble and rod mills are built to last We are still filling parts requests for mills sold over 60 years ago Patterson mills are available in a wide variety of standard sizes and Ball Mills, Pebble Mills, Material Processing Mills Hatboro Ball mill grinding machines are valuable tools in various industries, offering efficient and reliable grinding and mixing capabilities Understanding their working principle, different types, parts, applications, advantages, and recent developments helps to appreciate their significance and wideranging applications in industries such as cement Ball Mill Grinding Machines: Working Principle, Types, Parts

.jpg)

Wet Overflow Type Ball Mill and Applications

2024年1月12日 How Overflow Type Ball Mill Works Material Feed: The raw material is fed into the mill at one end and travels through the mill by rotation The feed enters the mill at a specific rate, ensuring a controlled grinding process; 2024年9月14日 Keuntungan Menggunakan Mesin Ball Mill Setelah Mengenal Mesin Ball Mill, nah dalam menggunakan Mesin Ball Mill memberikan berbagai keuntungan yang membuatnya menjadi pilihan utama bagi banyak pabrik dan perusahaan Berikut adalah beberapa 1 Mengenal Mesin Ball Mill : Penjelasan Lengkap Empat PilarHosokawa Alpine’s longestablished Super Orion SO ball mill range is available in three models that encompass the classic standard variant (SO), a more compact option (SOCL) and the SOSF, which has been specially designed with a slotted panel for manufacturing coarse to ultrafine mineral fillers and ceramic materials with a fineness value down to d 50 = 08µmSuper Orion Ball Mill SO Hosokawa Micron Ltd2012年6月1日 Ball mills can grind a wide range of materials, including metals, ceramics, and polymers, and can operate on a variety of scales, from laboratory to industrial (Monov et al 2013) The produced (PDF) Grinding in Ball Mills: Modeling and Process Control

.jpg)

Micro Ball Mill GT300 Beijing Grinder Instrument Co,Ltd

Micro Ball Mill GT300Order Information Item No Description Please order grinding jars and balls separately 248900001 Micro Ball Mill GT300, 220V, 50/60Hz 248900003 Micro Ball Mil GT300, metal plate cover, 220V,50/60Hz Grinding jars (screw threads MUNRO provide a wide range of Laboratory Mills Like: Sample Mill, Cutting Mill, Continues Floor crushing, Cyclone, Mill, Knife Mill, Disk Mill and more Ball Mill: A ball mill is a type of mill that uses balls made of hardened steel to grind the sample material The balls are placed in a rotating drum and grind the sample by friction and Mills Laboratory Mills2023年10月10日 The Autogenous Mill remains an integral part of the milling process in many mining operations today Its unique ability to take advantage of natural material properties sets it apart from other types of mills available in the market Ball Mill The ball mill is one of the most commonly used grinding machines in various industriesUnderstanding the SAG Mill in Copper Ore Mining Process2024年1月1日 Ball mill is a type of grinding equipment that uses the rotary cylinder to bring the grinding medium and materials to a certain height and make them squeeze, impact, and grind and peel each other to grind materials Ball mill is the key equipment for crushing materials after they are crushed It is widely used in cement, silicate products, new Ball Mill SpringerLink

.jpg)

Ball Mill Adalah? Prinsip Kerja, Bagian, Komponen Dan

2022年10月5日 Ball Mill menjadi salah satu mesin yang sangat penting dalam proses produksi di suatu industri seperti dalam pembuatan cat, keramik, semen, kembang api, batu bara, pigmen feldspar dan serbuk material 3d printing, dll2013年8月3日 In Grinding, selecting (calculate) the correct or optimum ball size that allows for the best and optimum/ideal or target grind size to be achieved by your ball mill is an important thing for a Mineral Processing Engineer AKA Metallurgist to do Often, the ball used in ball mills is oversize “just in case” Well, this safety factor can cost you much in recovery and/or mill liner Calculate and Select Ball Mill Ball Size for Optimum Grinding2021年12月10日 Ball mills are connected to crusher silos and soil can be poured from each crusher silo according to the required slurry formulation The produced slurry of each ball mill is entered to one or more rotating slip tanks Fig 6 schematically illustrates the inlet and outlet material flows for ball millsHierarchical framework for maintenance and production scheduling of 2018年8月22日 For general cleaning of agate balls or grinding jars it is often advisable to mill for a short time some quartz sand, coarsely crushed uncoloured container glass, or small broken pieces of window What is the cleaning process for balls in Ball mill process?

Ball Mills in the Mineral Processing Industry MechProTech

2024年5月27日 The General Function of Ball Mills A ball mill is a grinder used for grinding and blending materials for mineral dressing processes, paints, pyrotechnics, ceramics, and selective laser sintering Appearance Ball mills have various designs and functions, ranging from laboratoryscale versions to large industrial models2022年7月12日 Vertimill® has 50% less footprint than a ball mill Lower operating cost Vertimill® is an energy efficient grinding machine They tend to grind more efficiently than, for example, ball mills with feeds and continues to be operated beyond its design After a challenging commissioning and optimization process, the HIGmill™ exceeds Stirred mills MetsoWELCOME TO VEC Chocolate Machines Pvt Ltd We are a reputed manufacturer of Automatic/SemiAutomatic Chocolate Moulding Machines, manual Moulding and Tempering Machines, VECSupreme Continues Chocolate Tempering Machine, Chocolate Refiner Conches, Ball Mill Process Chocolate Line, Chocolate Enrobing Machines, Caramel Enrobers, Cooling VEC Chocolate Machines Pvt Ltd Chocolate machines2024年4月29日 Ball mills are widely used for size reduction in mineral processing, but effective scaling from laboratory to industrial scale remains challenging This study introduces a novel scaling constant approach to replicate energy transfer to ore during milling across different scales by adjusting rotational speed and grinding medium size distribution The scaling constant Scaling Energy Transfer in Ball Mills: A ScaleAgnostic

.jpg)

What is a Ball Mill Explained: InDepth Guide JXSC

2024年4月28日 A ball mill is a kind of grinder that grinds and blends materials for the purpose of mineral processing, paint production, pyrotechnics, ceramics, and selective laser sintering This results in smaller particles of the ore particles On the other hand, this process continues until the size of the ore particles reaches the desired size The Neumann Machinery Company (NMC) ball mills have a long and proven history going back to the early 1900’s The first mill designs originated from EIMCO Company originally located in Salt Lake City, Utah The current designs take advantage of advanced technologies in manufacturing, controls and devices NMC continues the tradition of reliable Custom Ball Mill Products Neumann Machinery CompanyBall mills are used the size reducing or milling of hard materials such as minerals, glass, advanced ceramics, metal oxides, solar cell and semiconductor materials, nutraceuticals and pharmaceuticals materials down to 1 micron or less The residence time in ball mills is long enough that all particles get consistent treatment, which also Ball Mill Application and Design Paul O AbbeHowever, when the filling rate continues to rise beyond a certain point, the internal space of the ball mill becomes more crowded, causing the media in the shoulder area to converge towards the middle and toe areas of the mill Consequently, the height difference between the shoulder and toe areas starts to diminish as the toe area accumulates Understanding the EnergySaving mechanism of ceramic balls

.jpg)

Laboratory Mills MRCLab

A typical type of fine grinder is the ball mill A slightly inclined or horizontal rotating cylinder is partially filled with balls, usually stone or metal, which grinds material to the necessary fineness by friction and impact with the tumbling balls Continues Cutting mill 5kg/hour 20/40/60 mesh sieves 1 CM20000 Continues Cutting mill High Energy Ball Mills Retsch 产品 粉碎设备 High Energy Ball Mills Ultrafine grinding at 2000 rpm 高能球磨仪E max Sample volume up to 2 x 45 ml Final fineness*: 008 µm Highly effective size reduction mechanism Retsch : 产品 : 粉碎设备 : High Energy Ball MillsThe process of fusion and folding continues until complete homogenization is achieved after a few minutes or several hours Diminutive crystalline sections of adjacent initial components are formed in the powder particles which are called “nano crystallites” The Planetary Ball Mill PM 300, with its large sun wheel and a maximum speed Mechanical Alloying with Ball Mills Retsch2017年2月13日 Ball Mills or Rod Mills in a complete range of sizes up to 10′ diameter x 20′ long, offer features of operation and convertibility to meet your exact needs They may be used for pulverizing and either wet or dry grinding systems Mills are available in both lightduty and heavyduty construction to meet your specific requirementsBall Mills 911Metallurgist

What’s the Difference Between SAG Mill and Ball Mill

2019年11月26日 Difference Between SAG Mill and Ball Mill, from the working principle, application, structure, etc Grind and blend solid or hard materials into smaller pieces by means of shear, impact and compression The internal machinery of the ball mill grinds the material into powder and continues to rotate if extremely high precision and precision 2024年10月30日 Features of Ball Mill Ball mill is used for grinding ceramic raw materials The intermittent ball mill depends on the rotation and relative sliding of the ball grindstone to meet the material’s fineness requirement Excellent engineering RD team continues to innovate technology Export to more than 100 countries and successfully Ball Mill Grinding for Grinding Ceramic Raw MaterialsA ball mill operates by rotating a cylinder with steel or ceramic balls, causing the balls to fall back into the cylinder and onto the material to be ground The rotation of the cylinder is typically between 4 to 20 revolutions per minute, depending on the diameter of the millA Comprehensive Guide to Ball Mill Manual ball mills supplierFig2 Description of continues ball mill 1 • Continues ball mill : To grind the material continuously that, to feed from one end and to collect the discharge in a cyclone from other end with the help of a fan The classifier may be of mechanical type or for a very precise fine separation variable speed motor driven classifier is also availableBall Mill

.jpg)

Ball Mill Success: A StepbyStep Guide to

2024年8月8日 Ball Mill Success: A StepbyStep Guide to Choosing the Right Grinding Media {{lastDate}} Introduction In the intricate dance of ball milling, where raw materials are transformed into finely milled particles, the choice of The Alpy Continuous Ball Mill, a highly efficient chocolate ball mill, is designed for the micronization of chocolate, compound, and cream Two models has different capacities for different needs ACB500 Model with 1300 kg balls has 400500 kg/h capacity with powder sugar ACB1000 Model with 1800 kg balls has 8001000 kg/h capacity with Continuous Ball Mill Chocolate Ball Mill from Alpy Machinery2015年4月24日 2 Ball mill consist of a hollow cylindrical shell rotating about its axis Axis of the shell horizontal or at small angle to the horizontal It is partially filled with balls made up of Steel,Stainless steel or rubber Inner surface of the Ball mill PPT Free Download SlideShare6 天之前 DOVE Ball Mills are supplied in a wide variety of capacities and specifications DOVE small Ball Mills designed for laboratories ball milling process are supplied in 4 models, capacity range of (200g/h1000 g/h) For small to large scale operations, DOVE Ball Mills are supplied in 17 models, capacity range of (03 TPH – 80 TPH)Ball Mill Ball Mills Wet Dry Grinding DOVE

Ball Mills vs Rod Mills 911Metallurgist

2017年7月3日 How do you decide between using a ball mill or a rod mill? Many investigators have attributed the selective grinding of rods to line contact Other things should be considered In the two pairs of tests shown in table 12 the relative deportment of large balls and small rods in batch wet grinding is shown The two loads had the same volume2006年12月12日 With nearly 400 mills installed worldwide, our skill and reliability in supplying machines for this crucial stage of production are undisputed As part of its ongoing product improvement strategy, SACMI has now launched the new MMC range, which improves productivity and efficiency by up to 15% with respect to traditional continuous mills and so MMC: SACMI continues to innovate continuous grinding2015年11月30日 The document discusses the ball mill, which is a type of grinder used to grind materials into fine powder It works on the principle of impact and attrition, where balls drop from near the top of the shell as it rotates to grind materials placed inside A ball mill consists of a hollow cylindrical shell that rotates about its axis, with balls Ball Mill PPT SlideShareOur ball mill grinder is a versatile tool designed for grinding and blending materials into fine particles Its cylindrical chamber houses the grinding medium—be it metallic or ceramic balls—allowing for smooth, efficient milling Widely used in industries such as mining, ceramics, and pharmaceuticals, this grinder operates through rotation Ball Mill Grinder Wet Dry Grinding Ball Mill Labotronics

A DEM based scaleup model for tumbling ball mills

2022年9月1日 A simulation started with the formation of a packed bed of the balls and powders in a still mill (Fig 1 a)The mill then rotated at a given speed to lift the ballparticle mixtures (Fig 1 b)After the flow reached the steady state as shown in Fig 1 c (by monitoring flow velocity), the flow dynamics information was then collected and analysed It should be noted the change of Ball mill girth gear Rotary kiln thrust roller Ball mill trunnion Rotary kiln pinion Ball mill head Rotary kiln roller shaft Ball mill bearing bush Rotary kiln bearing housing Ball mill bearing housing ManufacturerFactory Rotary kiln spring plate ManufacturerFactory Ball mill transmission connection ManufacturerFactoryBall Mill Rotary Kiln Vertical Roller Mill Manufacturer Tongli