Manganese Ore Concentrating

.jpg)

How is Manganese Mined and Processed:

2024年4月9日 Mining and Concentrating There are several types of manganese ores: easy ore, which can be concentrated by washing and precipitation; refractory ore (carbonate and oxidized ores); and Pure manganese is produced by hydrometallurgical and electrolytic processes, while ferromanganese and silicomanganese are produced by the smelting of ores in a blast furnace Manganese processing Extraction, Uses Benefits Britannica2020年8月21日 Manganese is considered a relatively rare metal as concentrations of it in ore of commercial importance are geographically limited In nature, manganese is found in the form From Ore Body to High Temperature Processing of Complex Ores: Manganese Concentrating manganese ore involves several steps, and the specific methods used can vary depending on the type of ore and its mineral composition Here's a general outline of the How to concentrate manganese ore? zenithmineral

.jpg)

How to concentrate manganese ore? LinkedIn

2023年9月21日 Concentrating manganese ore involves a series of processes to remove impurities and increase the manganese content, making it suitable for various industrial 2015年8月27日 By the proposed technology, highquality concentrates of manganese, nickel, iron, and cobalt may be obtained Optimal enrichment parameters permit high levels of metal Production and use of concentrates from polymetallic manganese ore2020年8月13日 It has been demonstrated that manganese concentrate can be used for manganese smelting and for teels with low content of phosphorus, and that allows reducing Technology for producing highquality manganese 2021年1月1日 The study includes the results of direct irradiation of manganese ore pellets with concentrating solar flux in combination with the closedloop forced convection of airA Comparison of Direct Concentrating Solar Thermal

.jpg)

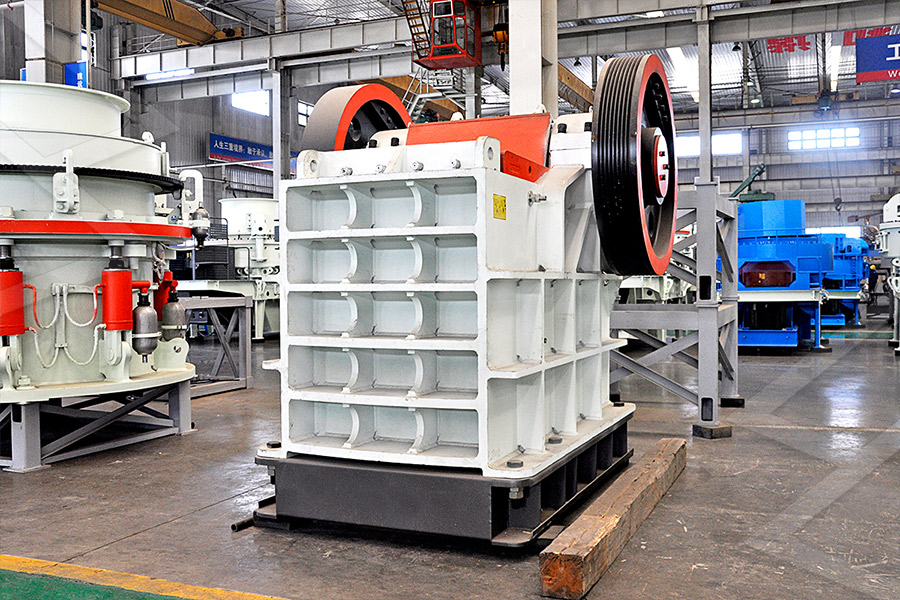

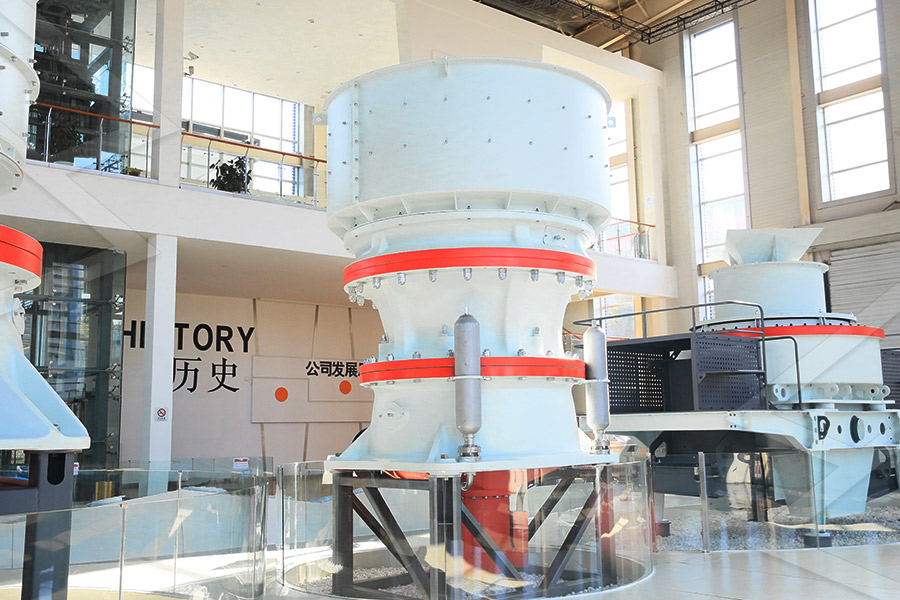

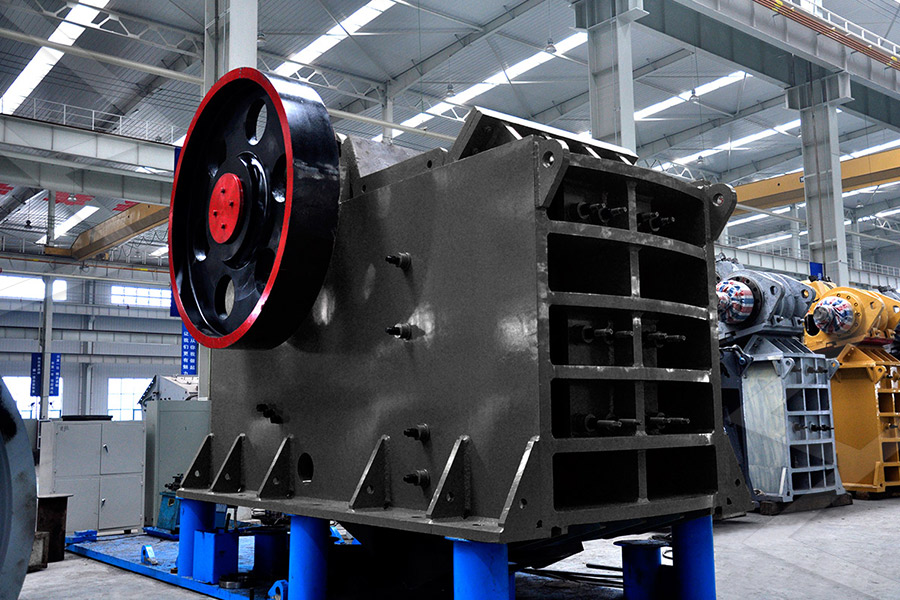

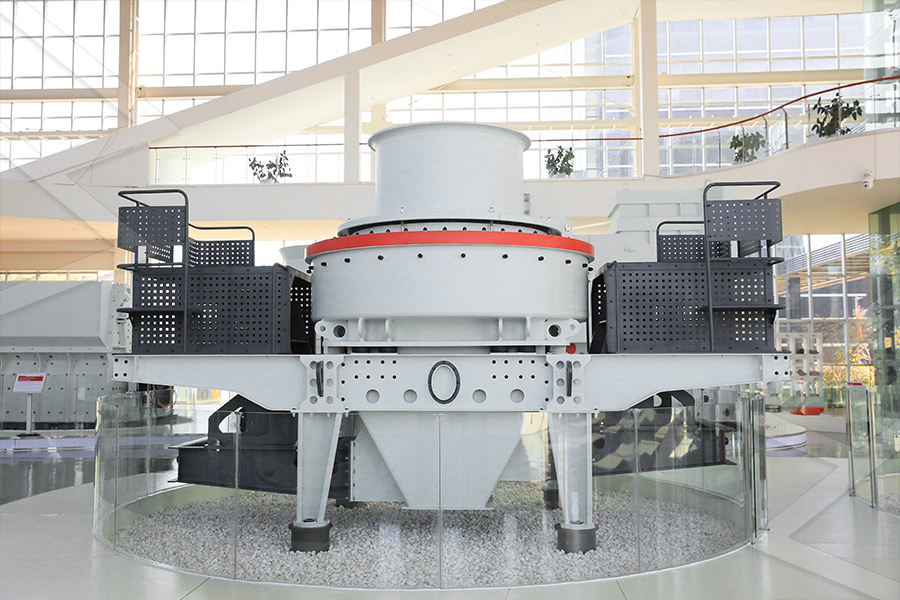

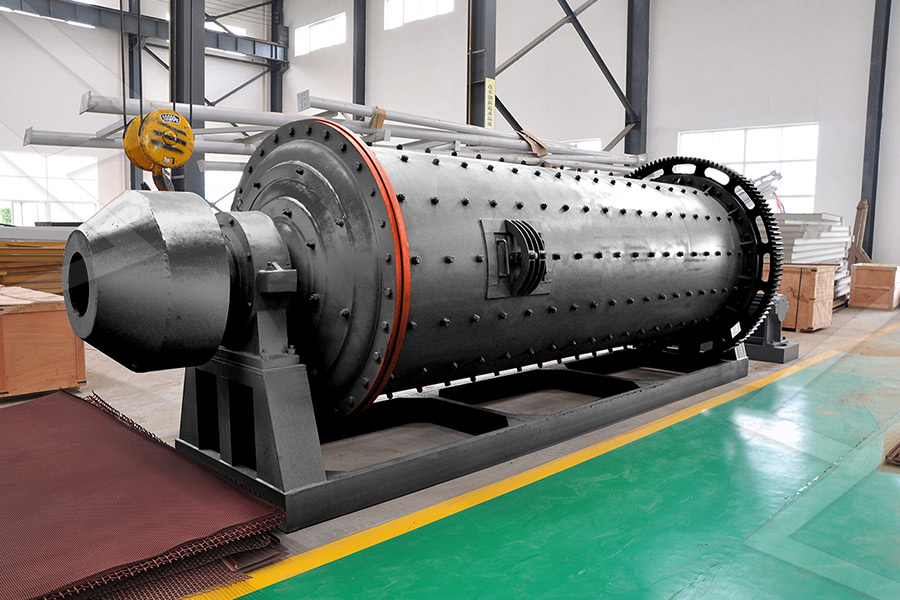

Concentration Process of Manganese OreMECRU

Concentration Process of Manganese Ore According to the characteristics and main uses of manganese ore, its processing technology mainly includes three processes: crushing, grinding Magnetic process is suitable for high phosphorus 、high silica、low iron manganese ore Process introduction 1Manganese magnetic concentration process2023年9月21日 Concentrating manganese ore involves a series of processes to remove impurities and increase the manganese content, making it suitable for various industrial applications The specific methods and How to concentrate manganese ore? LinkedInIt is believed that manganeseconcentrating microbes facilitate its formation Seafloor Manganese Ore: Manganese nodule collected in 1982 from the Pacific Ocean Manganese nodules are often rich in manganese, iron, nickel, copper, and cobalt The nodule is about four inches across Creative Commons image by Walter KölleManganese: Nodules, Uses, Facts, Ore, Alloys, Metal

.jpg)

Location of the Kalagadi Manganese sintering

The study includes the results of direct irradiation of manganese ore pellets with concentrating solar flux in combination with the closedloop forced convection of air The results of this study 2020年9月9日 Manganese ore is smelted to produce Manganese ferroalloy, a key component in steel production The smelting process is highly energy intensive, with temperatures up to 1600 ?Concentrating Solar Thermal Process Heat for Manganese 2024年10月22日 Manganese (Mn) is the twelfth most abundant element in the Earth’s crust Amongst some 300 minerals containing manganese, only about a dozen are of economic significance Manganese is a silverygray metal that resembles ironIt is hard and very brittle, difficult to fuse, but easy to oxidizeManganese Ore Process Plant JXSC Mineral2023年1月6日 In the published investigations, manganese seems an afterthought with most concentrating on the recovery of nickel, Therefore, it is expected that TMC’s manganese silicate product will attract a premium to benchmark manganese ore prices Table 9 Valueinuse of TMC Mn silicate product compared to other scenarios assessed Full size tableUsing Polymetallic Nodules to Innovate Manganese Markets:

.jpg)

Manganese (Mn) Ore Minerals, Occurrence, Deposits

2023年4月23日 Manganese is a chemical element with the symbol Mn and atomic number 25 It is a hard, brittle, silverygray metal that is commonly found in the Earth's crust Manganese is an essential trace element that plays a crucial role in many biological processes, including metabolism, bone formation, and antioxidant function It is also used in various industrial 2019年8月23日 Most manganese ore is a finegrain, and contains phosphorus ore, iron ore and associated minerals, which brings a great difficulty to beneficiation processing At present, the commonly used manganese ore beneficiation methods are mechanical beneficiation methods (washing, screening, gravity separation, strong magnetic separation and flotation Manganese Processing Equipment, Process Flow, Cases JXSC2024年8月23日 Iron ores like magnetite, chromite and manganese ore like pyrolusite are concentrated by this process Sometimes, a reverse situation may occur: the ore is non magnetic and the gangue is magnetic Different chemical affinity between the ore and the gangue is utilized for concentrating the ore One example shown below will make this process Concentration of ore simplyscience2020年8月21日 Manganese is considered a relatively rare metal as concentrations of it in ore of commercial importance are geographically limited In nature, manganese is found in the form of oxides, carbonates, and silicates Manganese ores are complex in the sense that they not only consist of a complex oxide mineral assemblage but these minerals are also very finely inter From Ore Body to High Temperature Processing of Complex Ores: Manganese

.jpg)

Reduction of Manganese Ores in COCO2 Atmospheres

2020年11月20日 Comilog Ore Characterization of ore Comilog is a highlevel oxygen ore with a manganese content of approximately 50 pct, where the oxygen level (x in MnOx) is 194 to 195 (Table I)CaO and MgO are present in negligible amounts, whereas SiO 2 and Al 2 O 3 are detected in concentrations between 35 to 66 pct The content of chemically bound H 2 O was Metallurgical manganese ore samples from Ka'oje (Nigeria) were enriched to higher Metallurgical grades during wet gravity separation techniques which included Jigging and Tabling operations Asmined samples S1 (3683%MnO), S2 (4785%MnO), S3 (5885%MnO) and S4 (5496%MnO) were dressed and screened to 780+500 µm, 500+355µm, 355+250 µm, 250+192 µm and Responses of Ka'oje Metallurgical Manganese Ore to Gravity The study includes the results of direct irradiation of manganese ore pellets with concentrating solar flux in combination with the closedloop forced convection of air The results of this study Satellite image of the Kalagadi Manganese 2022年2月13日 Fig 1: Location of the Kalagadi Manganese sintering plant cluding the institutions associated with this paper’s authors 1 That project considers, amongst other activities, the solar preheating of manganese ore prior to entering INTEGRATING SOLAR PROCESS HEAT INTO

.jpg)

Location of the Kalagadi Manganese sintering plant

The study includes the results of direct irradiation of manganese ore pellets with concentrating solar flux in combination with the closedloop forced convection of air The results of this study 2016年1月14日 4 Introduction: Manganese ore in the form of ferro and silicomanganese alloys are the most essential ingredients in the production of steel, both crude and stainless Presently, India is the second largest importer of manganese ore in the world after China MOIL Ltd, a public sector company is the major producer of manganese ore, contributing about 46% of the total manganese beneficiation ppt PPT SlideShare2019年8月30日 The manganese ore pellets were made from manganese ore from the Kalahari Manganese Field deposit in South Africa The ore was pulverised and mixed with water and 3 % bentonite binder and then spinned on a disk to create pellets This method is identical to the preparation of mangane se ore pellets used in for previous results obtained withThe solar thermal treatment of manganese ore pellets 2 天之前 Manganese ore: Manganese ore is usually transported by truck and train from the mine to the buyer (Manganese alloy smelter or trading warehouse), and if exported, it is loaded on ships (usually in bulk, but sometimes in containers) China consumes 65% of the global output of Manganese ore (including 16% produced domestically), so around half of MANGANESE MINING AND TRANSPORT International Manganese

Satellite image of the Kalagadi Manganese sintering plant

The study includes the results of direct irradiation of manganese ore pellets with concentrating solar flux in combination with the closedloop forced convection of air The results of this study 2021年11月15日 Semantic Scholar extracted view of "Electrodialysis for concentrating cobalt, chromium, manganese, and magnesium from a synthetic solution based on a nickel laterite processing route" by G Feijóo et al Limonite is the surface zone of lateritic ore and it was considered an ore waste However, because of the demand, limonite is now Electrodialysis for concentrating cobalt, chromium, manganese2019年7月26日 The study includes the results of direct irradiation of manganese ore pellets with concentrating solar flux in combination with the closedloop forced convection of air The results of this study (PDF) The solar thermal treatment of manganese oreThe study includes the results of direct irradiation of manganese ore pellets with concentrating solar flux in combination with the closedloop forced convection of air The results of this study Satellite image of the Kalagadi Manganese

Simultaneous extraction of manganese from low grade manganese

2002年4月1日 Pure manganese dioxide was successfully produced from low grade pyrolusite ore (βMnO2) and sulphur slag First, the reduction of βMnO2, introduced as pure pyrolusite was studied using Other countries produced 14 MMT Manganese ore (wet) production decreased by 22% in 2009 to 35 million metric tons This amounted to 11 MMT in manganese units, and yearly decline of 23% Table 3 shows major manganese producer countries in 2009 (beneficiation) Any of the following methods is used for concentrating the ores, the various Hydrometallurgical Processing of Manganese Ores: A Review2003年3月1日 Characterization and calcination behavior of a lowgrade manganese ore, as a part of Mn ferroalloys production, was studied by XRF, exsitu XRD, insitu XRD, and SEMEDS techniquesMaking Sinter from Concentrate of LowGrade Manganese Ore 2020年2月1日 Manganese leaching during high concentration flue gas desulfurization process with semioxidized manganese ore was studied in this paper It was found that there were different reaction pathways among which MnO 2, Mn 2 O 3 and MnCO 3 in semioxidized manganese ore during flue gas desulphurization and manganese leaching High SO 2 Manganese leaching in high concentration flue gas desulfurization

.jpg)

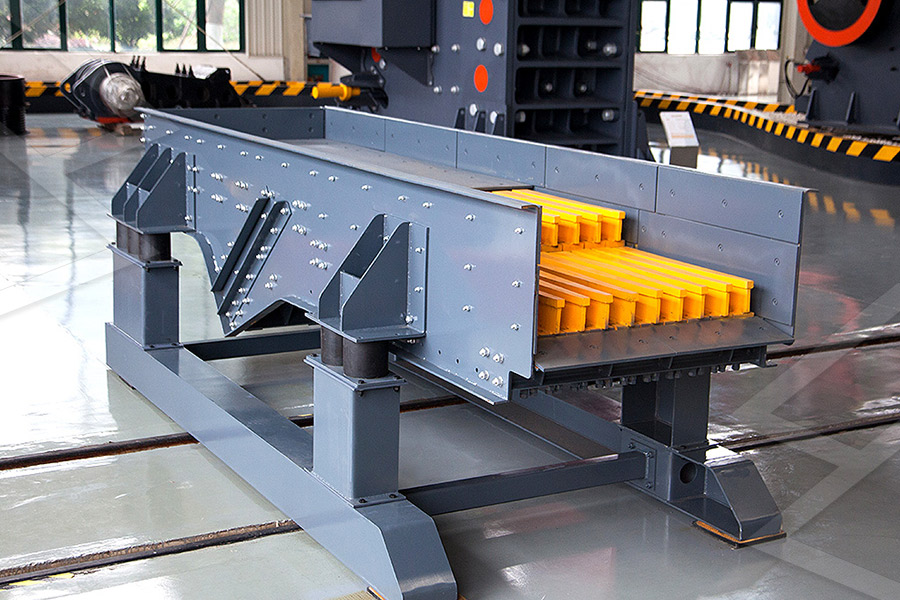

(PDF) Beneficiation of low grade manganese ore by jigging

In view of low threshold value (10% Mn) of manganese ore revised by Indian Bureau of Mines and considering high demand for ferromanganese grade ore, a silicate dominated lowgrade ROM ore assaying 2263% Mn (T) from Paunia area, Balaghat district, Madhya Pradesh was selected for beneficiation study This low grade ore was characterized in terms Full Sets Processing Manganese Ore Washing Machine US$4,800004,90000 / Set 1 Set (MOQ) Gold Diamond Mining Processing Machine Gravity Wilfley Wet Shaking Table Concentrating Zircon Tin Copper Gold Sorting Mineral Shake Concentration Mining Msi Vibrating Shaker Concentrator Price US$1,100001,49000 / Piece 1 Piece (MOQ)Trommel Screen Manufacturer, Rotary Scrubber, Shaking 2021年11月15日 Semantic Scholar extracted view of "Electrodialysis for concentrating cobalt, chromium, manganese, and magnesium from a synthetic solution based on a nickel laterite processing route" by G Feijóo et al Limonite is the surface zone of lateritic ore and it was considered an ore waste However, because of the demand, limonite is now Electrodialysis for concentrating cobalt, chromium, manganeseManganese ore gravity beneficiation production line is mainly composed of crusher, vibrating screen, washing machine, jig machine, dewatering screen and other equipment The raw ore enters the jaw crusher for coarse crushing, and then enters the secondary crushing According to the size of the beneficiation plant, we can use jaw crusher or cone Manganese Ore Processing Line Henan Forui Machinery

.jpg)

INTEGRATING SOLAR PROCESS HEAT INTO

2023年8月23日 MANGANESE ORE PREHEATING Recent technology innovation in the fields of concentrating solar energy is opening new potential markets to be considered for viability In particular, Stellenbosch 2024年9月5日 The technological processing flowsheet for goldbearing ores varies widely The choice of a particular technological flowsheet depends on several factors, including the nature of the gold in the ore, especially its size and chemical composition, the nature of the minerals associated with the gold, the presence of other valuable components in the ore, and the Gravity Concentration of GoldBearing Ores and Processing In view of low threshold value (10% Mn) of manganese ore revised by Indian Bureau of Mines and considering high demand for ferromanganese grade ore, a silicate dominated lowgrade ROM ore assaying 2263% Mn (T) from Paunia area, Balaghat district, Madhya Pradesh was selected for beneficiation study This low grade ore was characterized in terms (PDF) Beneficiation of low grade manganese ore by jigging 2019年1月15日 Manganese is an important metal with wide industrial applications in many aspects of social economy Approximately 90–95% of manganese are consumed in the steel production, and the rest are used in the fields of nonferrous production, battery, and dietary additives (Tan et al, 2004, Mei et al, 2011, IMnI, 2008–2016, China Manganese Industry, xxxx)Extraction and separation of manganese and iron from

The Impact of Solar Resource Characteristics on Solar Thermal

2020年1月16日 The proposed paper evaluates an alternative ferromanganese production flowsheet seeking to preheat manganese ores with concentrating solar thermal energy to 600 \(^{\circ }\) C The benefits of solar thermal preheating will be evaluated based on a cost discounted economic model taking into account the variability of the solar resource, capital 2011年7月8日 The oreforming role of black shales is discussed Correlation of their distribution with high phosphorus and manganese concentrations is shown Associations of black shales, phosphorites, and manganese ores are described A mechanism is proposed for explaining their cooccurrence in natural environments It is emphasized that back shales serve as not only The role of black shales in the formation of phosphate and manganese PDF On Jan 1, 2020, Sifiso N Sambo and others published The Development of a Heat and Mass Transfer Model for a Shaft Kiln to Preheat Manganese Ore with Hot Air, Model Development Methodology (PDF) The Development of a Heat and Mass Transfer Model 2018年8月13日 Fig 1: Location of the Kalagadi Manganese sintering plant cluding the institutions associated with this paper’s authors 1 That project considers, amongst other activities, the solar preheating of manganese ore prior to entering INTEGRATING SOLAR PROCESS HEAT INTO

What is the process for mining manganese ore? LinkedIn

2023年2月7日 The process for mining manganese ore typically involves crushing and sorting the ore, separating it from waste rock, and then concentrating the extracted ore After this process is completed, the 2024年10月25日 According to a port contact, South African manganese ore stocks at Tianjin were 338 million tonnes on October 11, up by 52% on a weekly basis; Gabonese manganese ore stocks were 10 million tonnes, up by 72% on a weekly basis; Australian manganese ore stocks were 400,000 tonnes, down by 35% week on week; and Brazilian manganese ore GEMCO’s manganese ore suspension: a volatile market