Machin Required For Stone Crushing Equment

What Machines Do Stone Crushing Plants Need? Fote

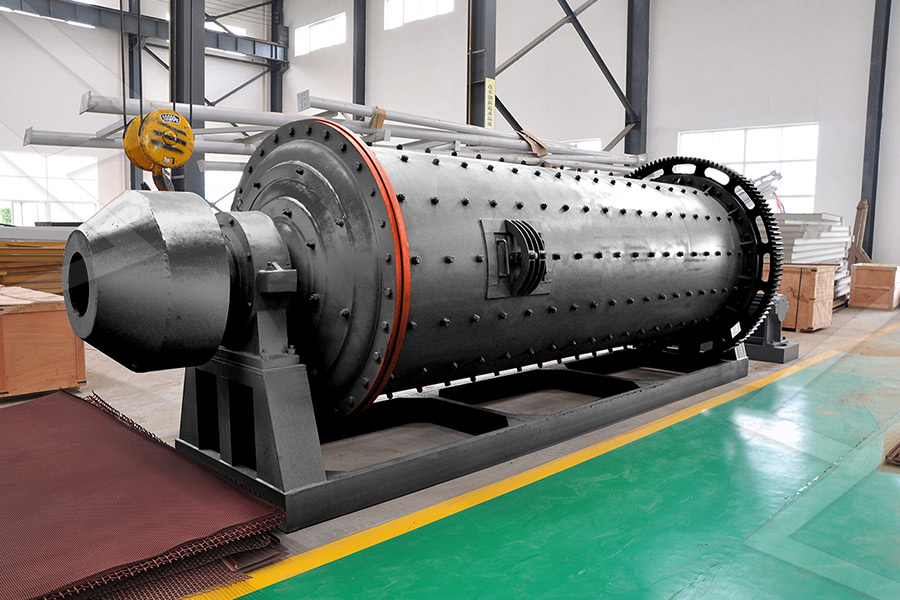

2024年10月14日 A stone crushing plant needs essential primary crushers like jaw and gyratory crushers as well as finecrushing equipment like impact crushers and ball mills Other critical heavyduty machines for the effective operation of a stone mill include the belt conveyors, Different types of crushing equipment are used at each stage to meet various crushing requiTypes of Crushers: Choosing the Right One for Each Stage2024年8月14日 Stone crusher is an indispensable part of crushing, sand making, grinding and other processes This article will tell you how to select the right crusher for your stone crusher 7 Types of Stone Crusher and How to Choose the Best?Setting up a successful stone crusher plant means balancing plant design, cost and efficiency But first, you’ll need to learn how to optimize your crushing setup while choosing the best machinery for your crushing needs This requires a Stone Crusher Plant Setup Machinery Partner

.jpg)

Types of Crushers: Choosing the Right One for Each Stage

2024年7月17日 Different types of crushing equipment are used at each stage to meet various crushing requirements Primary crushing breaks down large raw materials into mediumsized 2023年2月28日 Discover the best practices for designing a successful stone crusher plant, including factors to consider, equipment selection and configuration, environmental management, and safety and maintenance Stone Crusher Plant Design: Best Practices for 2023年2月22日 In this article, we will discuss the different types of stone crusher machines and their applications Primary Jaw Crusher: This type of jaw crusher is used for the first stage of crushing large and hard stones It is designed to Different Types of Stone Crusher Machines2024年6月30日 When selecting crushing equipment for a stone production line, there are several factors that need to be considered in order to ensure optimal performance and How to select crushing equipment for stone production line

.jpg)

The Ultimate Guide on How to Crush Stone: Techniques and Equipment

2024年10月10日 Harder rocks require more powerful crushing power from machines like jaw crushers and cone crushers, while softer rocks may be crushed effectively using less forceful 2024年6月26日 Summary: This guide provides essential information for selecting the most suitable primary stone crusher for your operation Different crusher types are analyzed, from Choosing the Right Stone Crusher for Primary Crushing2023年2月24日 Crushed stone machines play a critical role in the construction industry by crushing large rocks into smaller, more manageable pieces that can be used in a variety of Crushed Stone Machines: The Key to HighQuality Building A stone crusher typically consists of: Feeding Hopper: The section where stones are placed into the machine; Crushing Unit: The main mechanism that breaks the stones; Conveyor Belt: The belt that transports the crushed stones; The Stone Crushing Machine What is a Stone

.jpg)

(PDF) Design and Construction of Rock Crushing Machine

2018年8月7日 capable of crushing rocks, lime stone and solid minerals for indigenous use The research w ork was tailored mainly on the design and production of locally fabricated rock crushing machine for 2023年2月24日 Crushed stone machines play a critical role in the construction industry by crushing large rocks into smaller, more manageable pieces that can be used in a variety of building projects In this comprehensive guide, we explore the different types of crushed stone machines, their components, and how to operate them safely and efficiently We also highlight Crushed Stone Machines: The Key to HighQuality Building 2023年2月28日 Introduction: A stone crusher plant is a machine designed to reduce the size of large rocks, eliminate gravel, or rock dust to smaller sizes for various applications These plants find application in quarrying, mining, construction, and recycling operations Stone crusher plants consist of several components, including a primary crusher, secondary crusher, and vibrating Crushing it: A Comprehensive Guide to Stone Crusher PlantsThe energy required for crushing rocks was obtained by direct measurement of crusher#39;s motor power during the crushing of samples Laboratory tests were used to determine the following physical and mechanical properties of the tested samples: bulk density, compressive strength, tensile strength, hardness, and fracture toughness(PDF) Design of Impact Stone crusher machine Academia

.jpg)

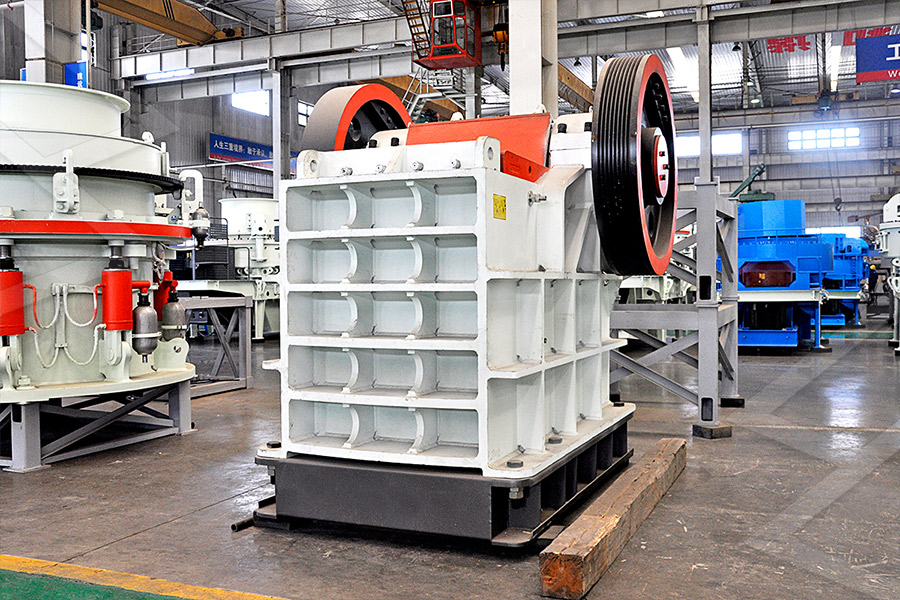

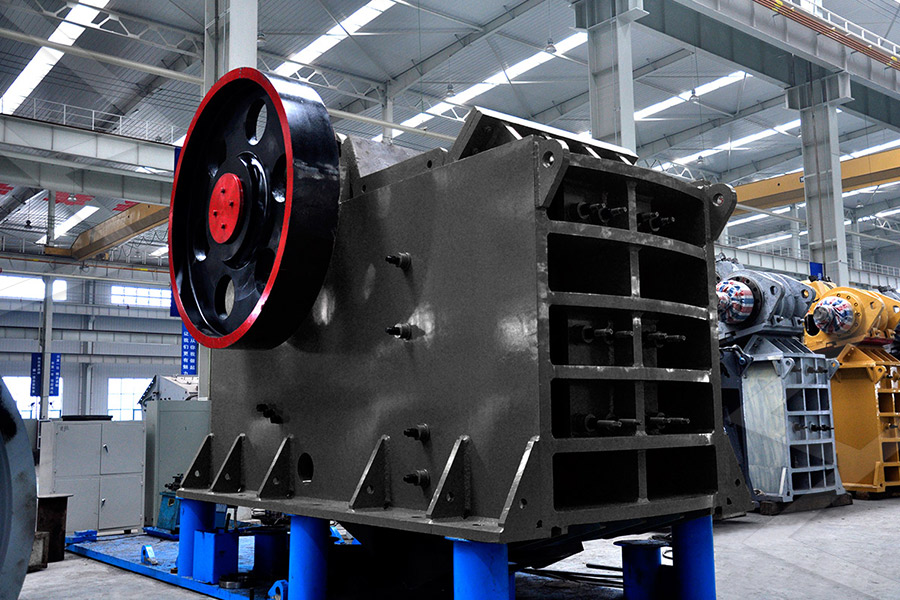

The Ultimate Guide to Jaw Crushing Machines: Types

2023年2月21日 A jaw crushing machine is a type of equipment used to break down hard materials, such as rocks, minerals, and ores It consists of a fixed jaw plate and a movable jaw plate that is positioned in a Vshaped configuration As the movable jaw plate moves back and forth, it crushes the material against the fixed jaw plateThe crushing of stone happens in two different stages The first stage happens when you manually introduce and feed the 175 mm stones to the crusher, which then reduces it to anywhere around 50 mm stone pieces Then one can fit the conversion kit to the stone crusher itself, which allows it to crush that 50 mm stone piece to any smaller size Stone Crusher Project Report Process Business Plan PDF India2024年7月19日 Stone crushing equipment can break down large rocks of different hardness into crushed stones suitable for different uses, maximizing the value of the material Many people may believe that breaking large rocks into small stones is a challenging task In fact, with the assistance of modern highefficiency stone crushers, this process is both How to Crush Stones: A Comprehensive Guide Fote 2022年5月14日 These finally crushed stones are again crushed according to the requirement of the customer A single type of crusher is not sufficient enough to convert the large size rock into required size stone So, the crushing process involves primary, secondary and tertiary crushers during the whole crushing cycle to achieve the required dimensionStone Crushers: A Technical Review on Significant Part of

Stone Crusher Machine Price: Factors, Range, and Ways to

2023年2月28日 Stone crusher machines are used in various industries for crushing different types of materials such as rocks, stones, and minerals These machines are an essential part of many construction and mining projects as they help in reducing the size of raw materials and making them usable for further processing2023年2月15日 The Blake jaw crusher has a fixed jaw and a moving jaw pivoted at the top The crushing chamber is made up of two jaws, which are lined with manganese steel plates The Blake jaw crusher is the most commonly used jaw crusher in the stone crushing industry It has a high crushing capacity, and it is easy to operate and maintainA Guide to Types of Jaw Crushers for Crushing Rocks and Stone Crusher JXSC company stone rock crushers include cone crusher, jaw crusher, impact crusher, mobile crusher, sand making machine, mobile crushing plant hammer crushing which can crush with more than 200 kinds of industrial materialsSuch as pebble, granite, basalt, iron ore, limestone, quartz, diabase, iron ore, gold, copper, etc Primary and fine crushers are the Stone Crusher Cone Jaw Crushers Machine Manufacturer3 天之前 MEC’s stone machines are ideal solutions for companies that need to process and shape various types of stone These powerful and versatile machines are designed to cut, split, crush, and finish stone materials with Stone machinery MEC

.jpg)

Stone Manufacturing Equipment in Uganda Jijiug

Jijiug More than 17 Stone Manufacturing Equipment for sale Price starting from USh 15,000,000 in Uganda choose and buy today! Make better Stone crushing machine from 8ton to 20 ton capacity per hour Popular Quick reply DIAMOND USh 40,000,000 Big Looking for highquality stone crushing equipment that is both efficient and reliable? Look no further than our company! Our equipment is designed to meet the specific needs of customers in a range of industries, including hydroelectric station, building materials, highway, railway, and urban constructionCrushing Equipment, Stone Crushing Equipment Fodamon MachineryOur engineers have designed a variety of rock and stonecrushing equipment capable of completing any job you may have Although most of our equipment is constructed for heavyduty, industrial projects, we do offer machines for smaller stone crusher applications Turn to the industry leader in crushing and screening for your size reduction needsRock Crushers Pulverizers Williams Crusher2024年6月9日 A questionnaire survey was conducted in stone crushing industrial area of Sargodha, Pakistan to assess its harmful health and economic impacts on workers engaged in different activities of stone (PDF) StoneCrushing Industry and Housing Demand in

Mineral Processing Equipment for Mining Industry

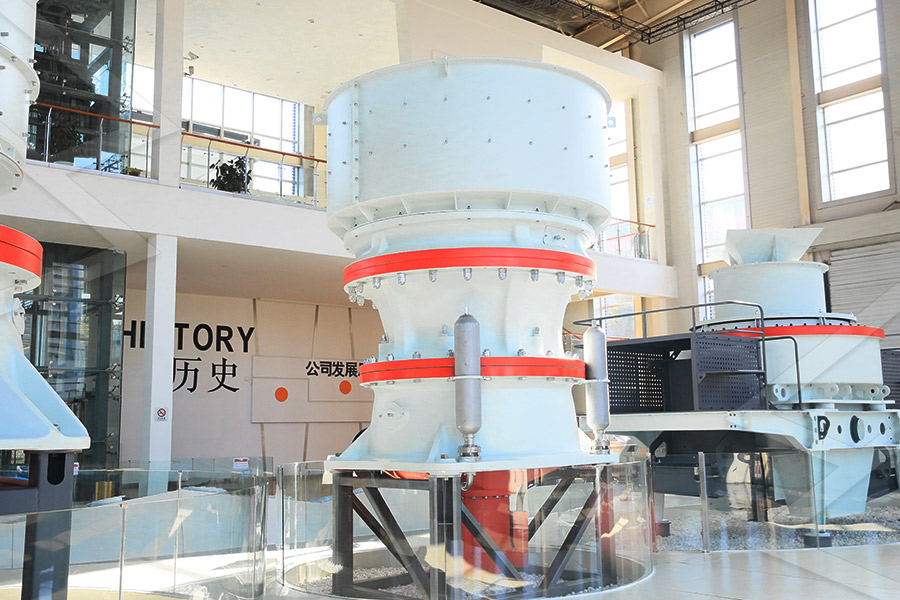

2024年8月7日 Crushing Equipment: Essential in mineral processing, crushing breaks down large ore blocks into smaller, manageable pieces for further processing Primary crushing is the reduction of significant ore particles into smaller bits using jaw crushers Key types include Jaw Crushers, which handle large rocks and ores through compressive force 2023年6月3日 Stone crushing and quarrying activities have a significant impact on both human health and environmental quality The current study was carried out to evaluate the environmental impacts of Environmental Impact Assessment of a typical Stone Crushing 2023年2月22日 Stone crusher machines are widely used in the construction and mining industries to break down large stones into smaller pieces To ensure that these machines operate efficiently and remain in good condition, regular maintenance and repair are necessary In this article, we provide a comprehensive guide to the maintenance and repair of stone crusher Maintenance and Repair of Stone Crusher Machines2020年3月19日 Directly related to crushing, the kilowatts ultimately dictate whether the engine will meet the operation’s output needs Strong brand name engines provide a proven track record and the network required to ensure service and support whenever and wherever the operator/contractor needs itSelecting the right crusher for your operations Quarry

.jpg)

The Stone Crushing Business in Pakistan: Opportunities and

2024年10月24日 The stone crushing industry in Pakistan plays a vital role in supporting the country's burgeoning construction and infrastructure development sectors As a thriving segment of the economy, this industry is primarily concentrated in the northern regions of the country, particularly in the resourcerich provinces of Khyber Pakhtunkhwa and Punjab 2020年4月30日 Stone crushing and quarrying activities have considerable effects on environmental quality and human health Present study was conducted to assess environmental perspectives of various stone (PDF) Environmental Perspective of Stone Crushing andLapidary supplies, equipment, and jewelry tools on sale include carving burs, cabbing wheels, diamond blades, and more in stock shipped same day! Tools from Diamond Pacific, CabKing, MK Diamond, HiTech Diamond, Eurotool, Revere, GRS Foredom including Nova Points, Galaxy Nova Wheels, Sintered Burs, and more!Lapidary Machines, Equipment, Jewelry Supplies for sale – 2024年9月24日 The fundamental goal for the design of a crushing plant is an installation that meets the required production requirements, operates at competitive cost, complies with today’s tough environmental regulations, and can be built at a reasonable price despite the rising costs of equipment, energy and construction laborCrushing Plant Design and Layout Considerations 911

.jpg)

Stone Crushing Machinery MadeinChina

The Stone Crushing Machinery is a key item within our extensive Mining Crusher selectionSourcing mining crushers wholesale offers cost savings due to bulk purchase prices, quality assurance through direct relationships with suppliers, and customization options to suit specific operational requirements Wholesale procurement ensures consistent 2020年11月8日 Crusher; Crushing; and Classification Equipment Download as a PDF or view online for free Sand and stone aggregate, metal mine, metallurgy, coal mine, mineral processing, building materials, chemical industry, abrasive, renewable resource utilization and other industries 90Crusher; Crushing; and Classification Equipment PPT2024年6月26日 Summary:This guide provides essential information for selecting the most suitable primary stone crusher for your operationDifferent crusher types are analyzed, from traditional jaw and gyratory crusher to impact crusher What Is a Primary Crusher? Primary crushing is the first step of most rock crushing processes within mining and other industrial Choosing the Right Stone Crusher for Primary CrushingMachinery For Sorting, Screening, Separating, Washing, Crushing, Grinding, Mixing Or Kneading Earth, Stone, Ores Or Other Mineral Substances, In Solid (including Powder Or Paste) Form; Machinery For Agglomerating, Shaping Or Moulding Solid Mineral Fuels, : Crushing or grinding machines: For stone and mineral: 06Jul0 Crushing or grinding machines: For stone and

.jpg)

Jaw Crusher or Hammer Mill: Which is Right for Your

2021年11月22日 Compact jaw crushers offer easy mobility to and maneuverability around tight quarry spaces and construction sites and can reduce 400squareinch and larger stones to manageable ¾inch to 3½inch piece – the ideal size for further size reduction and shaping in hammer mills Hammer Mill ApplicationsThe Nile stone and ore crushing production line features in high automation, high crushing ratio, KSh 770,000 Stable Performance Jaw Crusher China stone crusher With Competitive Pricestech, Inquiry Now KSh 77,000 What Brand of Stone Crusher Works Well Our constantly evolving offering for mining and rock drilling, crushing machine Support Stone Crusher Manufacturing Equipment in Kenya JijicokeStone crushing plants are essential to the construction industry, as they produce the following materials which are required at various stages of construction: (a) aggregates of various sizes (b) concrete blocks (c) ready mixed concrete (d) asphalt mix for road surfacing (e) rocksand ( as a substitute for coral sand which was banned in the EIA Guidelines for Proposed Stone Crushing Plants2023年4月13日 The quartz stone after medium crushing becomes a small stone of less than 5cm, and then it is finely crushed by the sandmaking machine to make sand After making sand, it becomes quartz sand of different Selection Of Quartz Stone Crushing And

253 Stone Crushing Equipment Industry PPTs View free

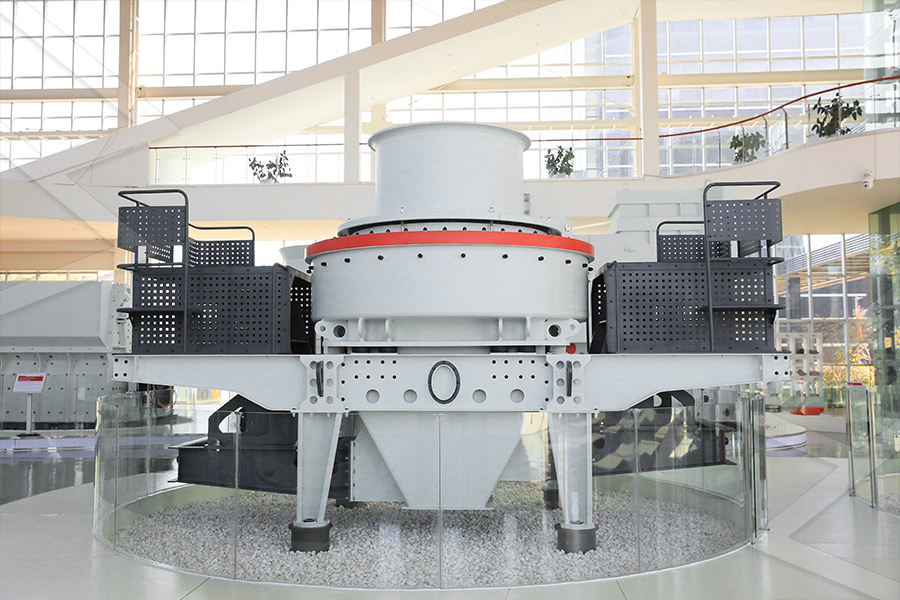

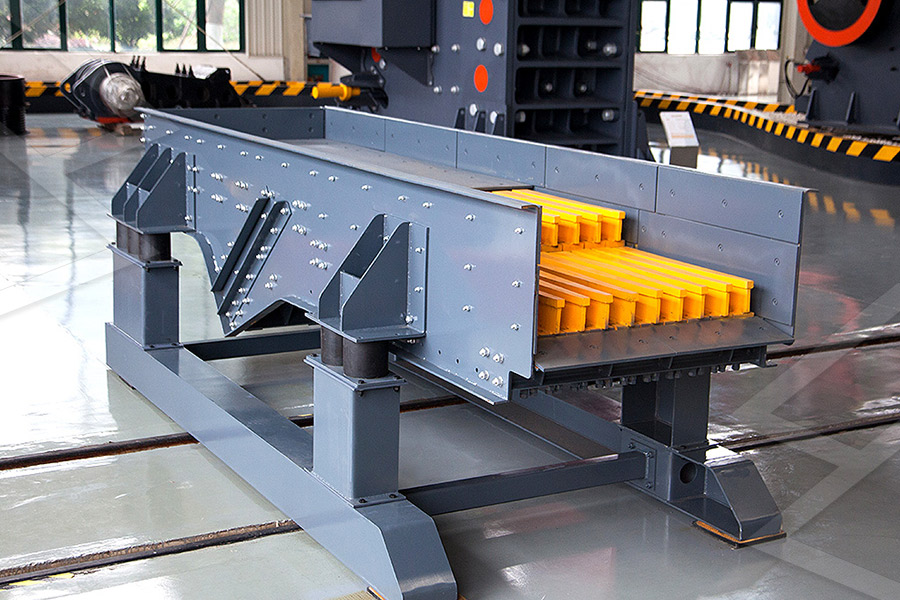

View Stone Crushing Equipment Industry PPTs online, safely and virusfree! Many are downloadable Learn new and interesting things Special equipment which can be transferred with minimum efforts is thus required for processing the materials which involves crushing into smaller parts and screening ie segregating different components of 2024年10月30日 system, a crushing system, a screening system, and a conveying system, among others Here is a detailed explanation of how the stone crushing plant works 1 Feeding The working process of the stone crushing plant starts from the feeding The raw stone is fed into the crushing plant by means of transport equipment such as trucks or conveyor beltsHow Does A Stone Crushing Plant Work Aimix Group 2024年10月14日 Horizontal Shaft Impact crusher (HSI) Impact crusher working animation The working principle of impact crusher is that the spinning rotor under the driving of the motor can genetate strong impact force which make blow bars crush stone material into small pieces Then the crushed material would be thrown by hammers towards, which makes another crushing 4 Types of Stone Crushers' Maintenance and Efficient 2023年2月28日 450t/h Stone Mobile Crushing Plant; 320t/h Construction Waste Material Crushing Station; 250t/h Limestone Mobile Crushing Plant; Tertiary crushers also offer improved efficiency over secondary crushers by reducing the number of crushing stages required to produce the final product However, the main disadvantage of tertiary crushing is the The Complete Guide to Primary Crushing, Secondary Crushing

.jpg)

A Comprehensive Guide to Stone Crusher Installation

2024年4月3日 The correct installation of stone crusher is imperative for safe and efficient longterm operation As key equipment in crushing applications, stone crusher equipment must be set up precisely according to engineering specifications This article provides a comprehensive guide to stone crusher installation procedures2024年3月2日 Secondary Crushing:After primary crushing, the intermediatesized river stones undergo secondary crushing to achieve the desired gradation and particle size Vibrating screens and sorting equipment ensure that the final product meets the specifications required for various applications, from concrete production to landscaping Washing and Choose the right river stone aggregate making crusher methodRock Crushing For Construction Projects Stone Production Line Product Category: Complete processing plant Favorites Product Introduction The production line using the impact crusher is twolevel breakingand has the advantages of simple process,good finished product (cube),investment economy and so onTheproduction line is especilly Rock Crushing For Construction Projects Stone Production