No Sieve Bottom Crusher Structure

.jpg)

10 aspects of differences between impact crusher and hammer crusher

2022年2月28日 The hammer crusher can only adjust the discharge opening by replacing the bottom sieve plate (new hammer crushers, such as heavy hammer crushers, generally have 2019年3月13日 A crusher is a major investment, so it’s essential to select one with the potential to meet your needs into the future This guide covers a few of the key points to consider before MASTER YOUR OUTPUT CRUSHER SELECTION QUICK 2020年6月1日 A parameter study using a jaw crusher is designed to investigate the influence of feed gradation, feed rate, crusher setting and crusher speed on the crusher operation and the Influence of jaw crusher parameters on the quality of 2021年5月17日 Indepth analysis of aggregates’ mineralogy, crushing, morphology, and degradation Lithotypes content and graintograin contact influence shape properties The influence of crushing processes and mineralogy of aggregates

The Influence of the Structure of Double Toothed Roller Crusher on

2018年10月1日 By means of orthogonal experiment, simulation analysis considers the influence factors of the roller spacing, the rotational speed and the pitch angle The best test scheme 2024年2月3日 Non Sieve Bottom Jaw Crusher Construction Waste Stone Sand Making Machine, Find Details and Price about Jaw Crusher Marble Jaw Crusher from Non Sieve Non Sieve Bottom Jaw Crusher Construction Waste Stone 2020年3月19日 A parameter study using a jaw crusher is designed to investigate the influence of feed gradation, feed rate, crusher setting and crusher speed on the crusher operation and the (PDF) Influence of jaw crusher parameters on the quality of The two rotor hammer crusher also called double hammer mill,it is improved based on the old single stage hammer crusher and is a new structure of the double level without a sieve bottom crusher/sbm no sieve bottom two stage crushermd at master crusher

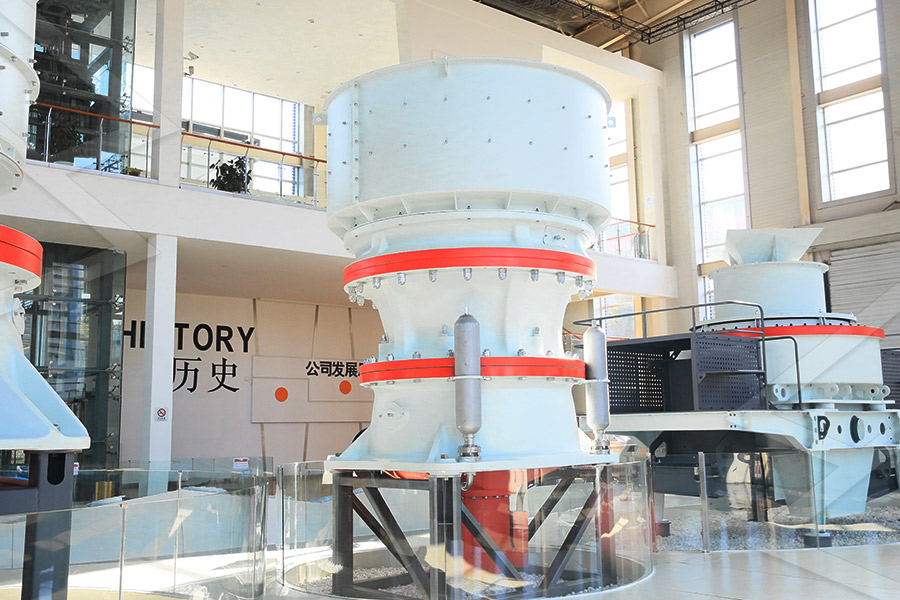

Evaluation of size reduction process for rock aggregates in cone crusher

2020年6月4日 In this study, 17 different rock types were considered for the evaluation of their size reduction variations that occurred in a laboratoryscale cone crusher Based on several RJ is a custom metal fabricator In 1990, we started as a small firm from making wear plate only After 30 years growth, today we are operating from our 3, 000 square meters manufacturing facility where we employ in excess of 30 peopleExcavator Attachments Manufacturer, Loader 2013年3月26日 In determining sieving time for sieve sizes larger than 475 mm (No 4), limit the material on the sieve to a single layer of particles Overload Determination • For sieves with openings smaller than 475 mm (No 4), the mass retained on any sieve shall not exceed 7 kg/m2 (4 g/in2) of sieving surfaceSIEVE ANALYSIS OF FINE AND COARSE AGGREGATESOur swing hammer crusher does not need the bottom of the sieve net, there is no strict requirement on the moisture content of the material, there is no problem of plugging the sieve plate The water content of the feed can reach 100%, the fineness of the discharge 90% is all in 2MM (less than mm), 1MM (less than mm) accounts for 70%, both dry Best Hammer Crusher Manufacturer, Rock Hammer Mill Crusher

Rotary Vibrating Screen LIGHT SIEVE EQUIPMENTProducts

MXS series threedimension rotary vibration sieve is a highprecision fine powder sieving machine It has the characteristics of low noise, high efficiency, contributing to quick changeover net (only 35 minutes) its fully enclosed structure is suitable for Sieving and filtering granular, powder, mucus and other materials, and no dust driftFor example, a No 4 (475mm) sieve has four holes per inch, while a No 18 (104mm) has 18: Micron or Micrometer: A common reference to particle size or opening dimension, properly defined as a micrometer: Nest: When a sieve with a skirt is stacked on top of another sieve of the same diameter, the two sieves are nestedSieve Sizes: A Guide to US and Metric Sizes Gilson CoWrite better code with AI Security Find and fix vulnerabilitiesfr/12/yanshi sieve clay crusher machinesmd at main2019年6月1日 By Sachin Mandavkar and Mehari Weldu Reinforced soil structures are geotechnical systems consisting of reinforcing elements and primarily include mechanically stabilized earth (MSE) walls and reinforced soil slopes (RSS) (Figure 1) MSE walls and RSS are constructed by placing alternating layers of reinforcement and compacted soil behind a facing Geogrid reinforced soil structures reach new heights

Limestone Crusher: An Edge Tool for Making Crushed

2024年7月15日 The impact crusher has more advantages in processing materials with high water content The feed chute and impact plate of the impact crusher can be equipped with a heating device to prevent the material from sticking And it has no grate sieve plate at the bottom, avoiding blockage262 views, 11 likes, 0 loves, 0 comments, 2 shares, Facebook Watch Videos from HotonMach: The internal rotor structure of the doublestage sieveless crusher: double rotor design, 90% of theThe internal rotor structure of the doublestage sieveless crusher 3 天之前 Rotary vibrating sieve, also known as rotary vibration filter sieve, The motor is equipped with eccentric hammers on the top and bottom to make the rotating motor move in horizontal, vertical and inclined directions Fully enclosed structure, low noise, no powder flying, no material pollution; 2 Made of stainless steel, smooth surface Rotary Vibrating Sieve JXSC Machinery2023年11月16日 Crusher run has unique properties that make it ideal for various construction applications Grading and Particle Sizes Crusher run contains a blend of stone, gravel, sand, and fine particles A typical gradation Crusher Run Gravel: Pave It Right With Our

crusher/sbm no sieve bottom two stage crushermd at master crusher

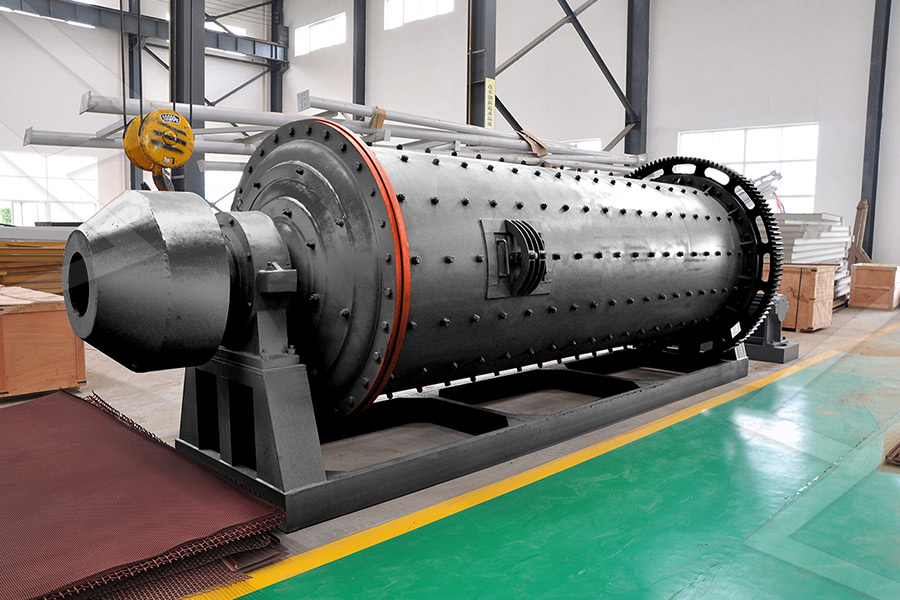

The two rotor hammer crusher also called double hammer mill,it is improved based on the old single stage hammer crusher and is a new structure of the double level without a sieve bottom crusher,this machine is a special type of coal stone and 2020年3月19日 A parameter study using a jaw crusher is designed to investigate the influence of feed gradation, feed rate, crusher setting and crusher speed on the crusher operation and the quality of the (PDF) Influence of jaw crusher parameters on the quality of Hammer Crusher Structure The industrial hammer crusher consists of machine body, rotor part, hammer head, impact plate, motor, sieve plate, feeding mouth, side plate, discharging mouth, etc After that, the gravity of materials themselves makes them hit against the impact plate and fall on the sieve plate at the bottom of the machine Hammer Crusher Hammer Mill Machine AGICO Hammer The Machine Structure of Lab Jaw Crusher: This series of jaw crusher is composed of machine body, eccentric shaft, belt pulley, fly wheel, movable jaw, side guard, gap adjustment screw, return spring, fixed jaw plate and movable jaw plate crushed and ground, then the end products come out from the bottom of this crusher Roll Crusher Mineral Beneficiation Laboratory Equipment Laboratory Jaw Crusher

.jpg)

Hammer crusher structure and working principleZYmining

2023年8月5日 Hammer crusher structure 1 Chassis The shell of the hammer crusher is composed of the lower machinery, the back upper cover, the left side wall and the right side wall, and the parts are connected together by screws, the top is built with a feeding port, and the inner wall of the shell is all lined with high manganese steel Inlay is convenient 2017年2月19日 All wearing parts are replaceable The crusher is fitted with a connection for introducing low pressure air inside the seal for additional dust protection Cone Crusher Eccentric, Gears, Pinionshaft The eccentric is made of high carbon cast steel and fitted with a bronze inner wearing sleeve The eccentric turns in a bronze bottom shell bushingCone Crusher Parts 911MetallurgistASTM Sieve Analysis Shakers RoTap Sieve Shakers, (8″, 12″ or 200 mm sieves) Range: ASTM No 635 (20 m) to ASTM 4″, (100mm) Screen Shaker Units, (for aggregates and wood chips, large screen area) Range: ASTM No 400 (38 m) to ASTM 5″ (125mm) Digital Sieve Shakers Digital Sieve Shaker, dry or wet sieving, Analysette 3 Spartan (8″ or Sieve Shaker, Sifter, Test Sieves LavallabCone crusher structure: cone crusher structure of the main frame, horizontal shaft, moving cone, balance wheel, eccentric sleeve, on the broken wall (fixed cone), under the broken wall (moving cone), hydraulic coupling, lubrication system, hydraulic system the material that has been broken to the required particle size falls under its own Gp300s 0 Concave for Mets0 Cone Crusher

.jpg)

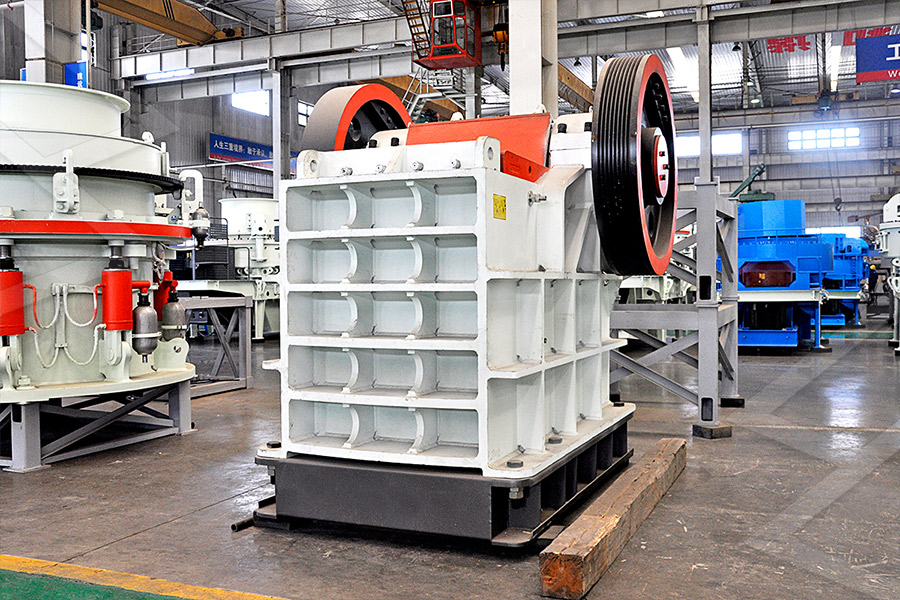

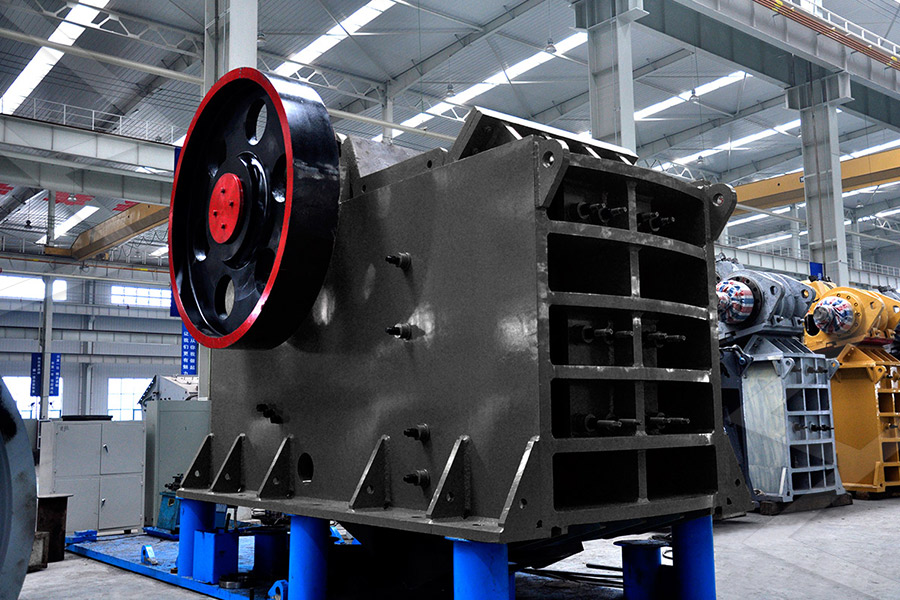

A Guide to Types of Jaw Crushers for Crushing Rocks and

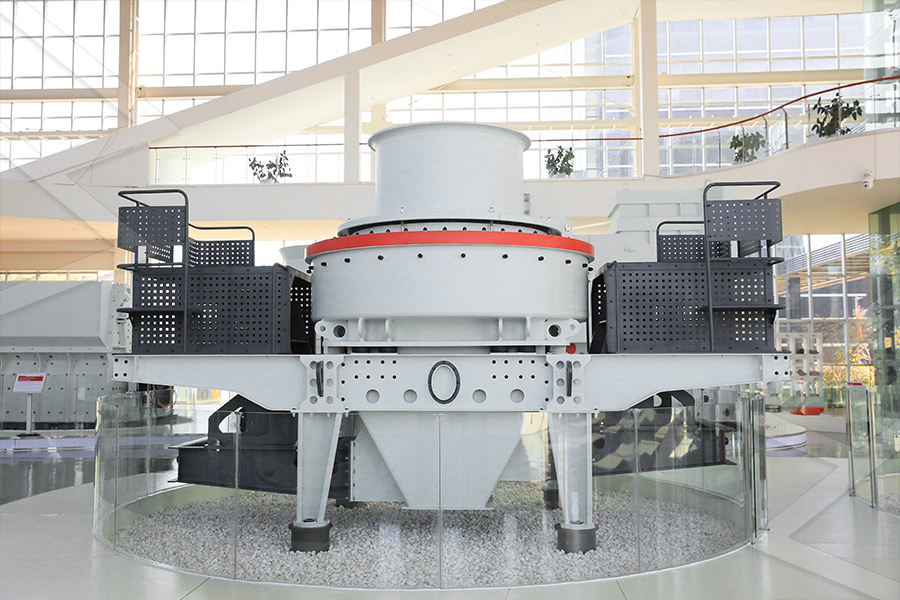

2023年2月15日 The single toggle jaw crusher is the simplest and most common type of jaw crusher In this type of crusher, the swing jaw is suspended on the eccentric shaft, which allows for a more compact design compared to other jaw crusher types The single toggle jaw crusher has a simple structure, low cost, and easy maintenanceOnce material strikes the anvils, it breaks and falls out the bottom of the crusher Cone Crushers Characterized by its central conical crusher component known as the head, a cone crusher operates around a main shaft to which the head is attached that rotates eccentrically within its crushing chamber to achieve the proper compressive force What Are Crushers? Eagle Crusher2024年6月4日 The TwoStage Fertilizer Crusher Machine also known as nosieve bottom crusher or twice crushing machine, it is divided into two stages of crushing It is an ideal crushing equipment that is well received by users in Cheap High Capacity TwoStage Fertilizer 2022年5月14日 Research study again represent the failure of supporting structure of crusher at early stage of installation but this time controlling of charge level according to different properties of stones has been observed as a reason of failure as it creates different deforming forces As a solution, automatic control of the steadystate setting of Stone Crushers: A Technical Review on Significant Part of

.jpg)

The Influence of the Structure of Double Toothed Roller Crusher on

2018年10月1日 Automation experimental studies of grinding process in jaw crusher using DEM simulation; Comparative analysis towards the use of needleshaped working body in sieve and sievefree multifaceted crushers; An Experimental Research of Biomass Crushing System; Optimization Design and Simulation Analysis for Cavity Shape of Single Toggle Jaw Crusher2024年10月31日 The mobile vibration sand screening and conveying machine is a multifunctional equipment with a complex structureIt consists of multiple components such as a vibrating screening part, a conveying part, a support structure, a control system, and moving parts to screen granular materials such as sand and gravel It is suitable for sand and gravel Mobile Vibration Sand Screening Machine JXSC Machine2024年7月15日 There is no grate at the bottom The product size is determined by the gap between the impact plate and plate hammer Therefore, it can process highmoisture materials Hammer crusher: It is equipped with a bottom sieve plate, which increases the possibility of material blockage 5 Different in outputImpact Crusher Vs Hammer Crusher: 8 Key Differences6 天之前 Sieve Arrangement – At Top 10mm, 475mm, 236mm, 118mm, 600µ, 300µ, 150µ at Bottom and Last Pan) Place the sieve set on the mechanical shaker and shake vigorously for at least 2 minutes Then measure the weight of aggregate retained on each sieve and express it as the percentage of passingSieve Analysis Of Sand: Procedure, Calculation Result

.jpg)

Effect of crusher rotational speed and moisture content on

Regarding the influence of sieve diameter on the crusher's specific energy under different crusher's rotational speeds, Fig 8 demonstrates that increasing sieve diameter decreased the crusher's cvb sieve for crusher donatimarco sieve hardox crusher horizon vhfvenw no sieve bottom crusher structure fromshayansangelsbe No Sieve Bottom Crusher Structure carteaverdeeu No Sieve Bottom Crusher StructureConcrete Mixing Plant this page is about concrete crusher with sieve hyderabad sieve hardox crusher horizon 6203 the bottom of the Get Price And Support sieve hardox crusher horizon 6203 batidosproteicosesCone crusher structure: cone crusher structure of the main frame, horizontal shaft, moving cone, balance wheel, eccentric sleeve, on the broken wall (fixed cone), under the broken wall (moving cone), hydraulic coupling, lubrication system, hydraulic system the material that has been broken to the required particle size falls under its own Gp500s N Concave for Mets0 Cone CrusherDownload Table Sieve Analysis for Crushed Coarse Aggregate from publication: A Comparative Study of the Methods of Concrete Mix Design Using Crushed and Uncrushed Coarse Aggregates The study Sieve Analysis for Crushed Coarse Aggregate

.jpg)

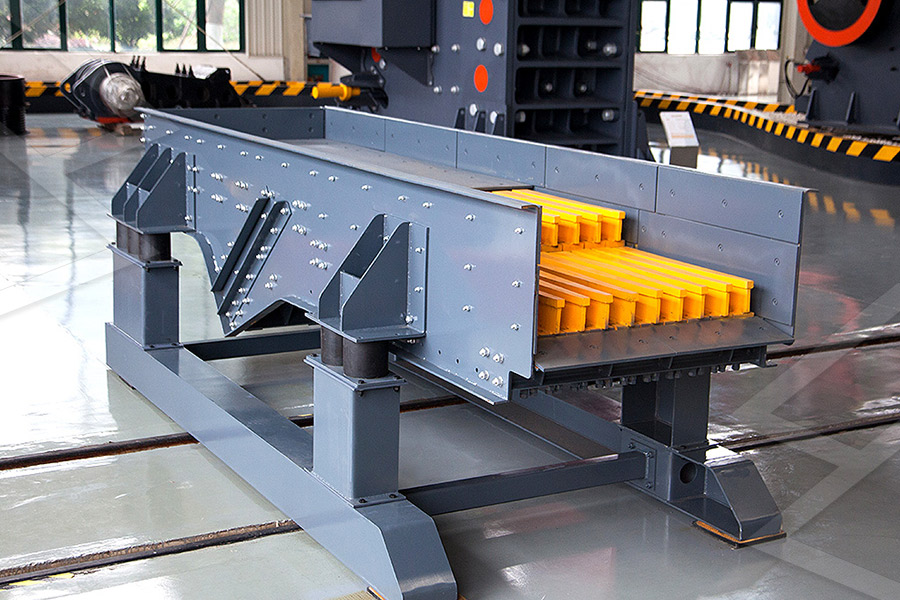

Vibrating Screen Crushing Mining Screen JXSC Mine

Sieve beams and sieve box connected by high strength bolts, no welding 4 Sieve machine has the advantages of simple structure and convenient repair 5 The small amplitude, high frequency, high dip structure, so this machine is of high efficiency, maximum, long life, low power consumption, low noise Screening Structure2015年5月13日 The primary crusher is normally a jaw crusher which is fed with blasted rock material As the size of the blasted material may vary greatly, the primary crusher has to have a large inlet(PDF) Cone Crusher Performance ResearchGate2018年1月23日 Specific gravity of crusher dust and natural sand is carried out as per IS 2720 (PartII) 1964 1 Specific gravity of crusher dust = 295 2 Specific gravity of natural sand = 271 52 Sieve Analysis of Crusher Dust For grain size distribution of crusher dust and natural sand, sieve analysis tests have been performed TheEffect of Crusher DustGeogrid Composite on Interface 2020年6月4日 The size reduction process of rocks in cone crushers is one of the most important issues, particularly for the secondary and tertiary stages of crushing operations In this study, 17 different rock types were considered for the evaluation of their size reduction variations that occurred in a laboratoryscale cone crusher Based on several mineralogical, physico Evaluation of size reduction process for rock aggregates in cone crusher

Aggregates for Concrete

2017年8月5日 order of size, with the sieve having the largest openings on top, the one having the smallest openings at the bottom, and a pan underneath to catch material passing the finest sieve (Fig 1) Sieve sizes commonly used for concrete aggregates are detailed in Table 1, and various physical properties of normalweightApr 11, 2020 The seven standard ASTM C 33 sieves for fine aggregate grading and as follows: Sieve size from top to bottom 3 / 8 in (95 mm) No4 (475 mm) No8 (236 mm) No 16 (118 mm) No 30 (600 μm) No 50 (300 μm) No 100 (150 μm) The thirteen standard ASTM C 33 sieves for coarse aggregate grading are as follows: Sieve size from top standard sieve sizes aggregate Welcome to Tables Thyme2023年4月21日 Soil crusher and sieve SSM3 ・ Crushing rollers are easily detachable ・ Gravels are escaped from crushing rollers , by adjusting the strength of springs aside the rollers Model SSM3 Crushing structure Hexagonal rollers Hopper material SUS304 Hopper volume Approx 1L Roller speed 83 rpm(50Hz)100 rpm(60Hz) Roller material StainlessSoil crusher and sieve SSM3 fujihiracojp2024年2月3日 Non Sieve Bottom Jaw Crusher Construction Waste Stone Sand Making Machine, Find Details and Price about Jaw Crusher Marble Jaw Crusher from Non Sieve Bottom Jaw Crusher Construction Waste Stone Sand Making Machine Zhengzhou Fude Machinery Equipment Co, LtdNon Sieve Bottom Jaw Crusher Construction Waste Stone

.jpg)

Types of Crushers: Choosing the Right One for Each Stage

2024年7月17日 A crusher, also known as a stone crusher, is a machine that uses mechanical action to break large rocks, ores, or other raw materials into gravel or rock powder material smaller than the discharge opening is released from the bottom The crushing action is intermittent Jaw crushers have a wide range of output capacities, making them