In Pit Crushing And Coal Conyeing In Queens Land

InPit Crushing and Conveying Systems in Longterm

2022年9月8日 One of the transportation options in surface mining to reduce operating costs, especially in the deep open pit mines, is InPit Crushing and Conveying (IPCC) In this paper, 2019年1月18日 InPit Crushing and Conveying (IPCC) systems are receiving more attention today due to current characteristics of openpit mining operations and what is expected to occur in the future Today, it has become more Inpit crushing and conveying technology in 2023年9月21日 Methods: This research aims to carry out a comparative analysis of different transportation systems, encompassing Truck–Shovel, Fixed InPit Crushing and Conveying (FIPCC), SemiFixed InPit Crushing and Truck–Shovel vs InPit Crushing and Conveying Rio Tinto Clermont Mine in Central Queensland uses an InPit Crushing and Conveying System (IPCC) for a major component of its overburden stripping for the mine The IPCC consists of a In Pit Crushing and Conveying (IPCC) Systems BMT

Modelling of InPit Crusher Conveyor alternatives

2014年1月11日 This paper investigates alternative IPCC configurations for prestripping application in an open pit coal mine It demonstrates that system redundancy in the form of 2019年1月18日 The present paper aims to provide a comprehensive literature review of all aspects of technical, economic and sustainable development of inpit crushing systems along Inpit crushing and conveying technology in openpit mining 2021年11月22日 For this purpose, this paper presents a mathematical integer programming (IP) model considering the operational constraints The model specifies both the optimum location Optimisation of openpit mine production scheduling Inpit crushing and conveying (IPCC) solutions not only offer cost savings by reducing the OPEX intensive truck fleet, but furthermore have enormous potential to reduce CO emissions and Inpit crushing and conveying: How it works and its

.jpg)

(PDF) Review of the inpit crushing and

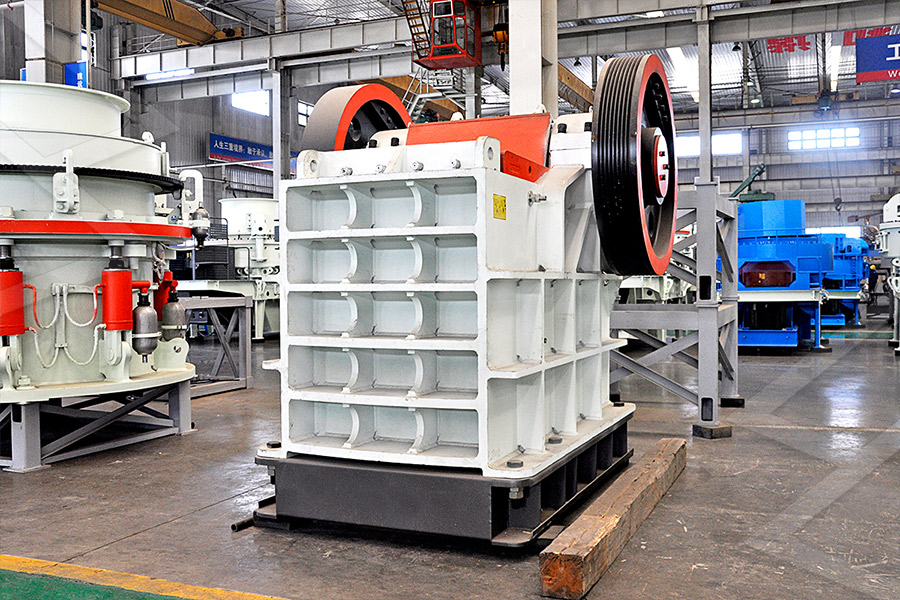

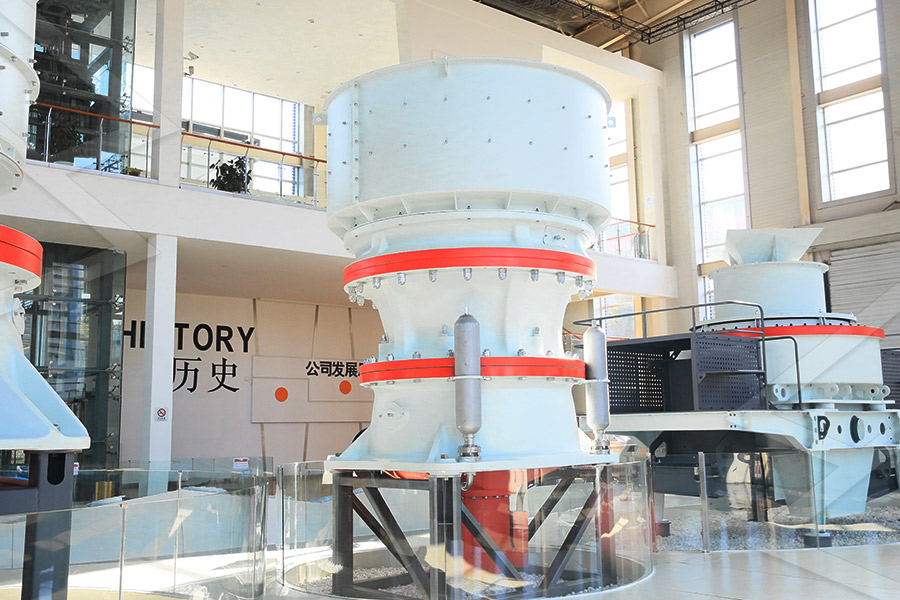

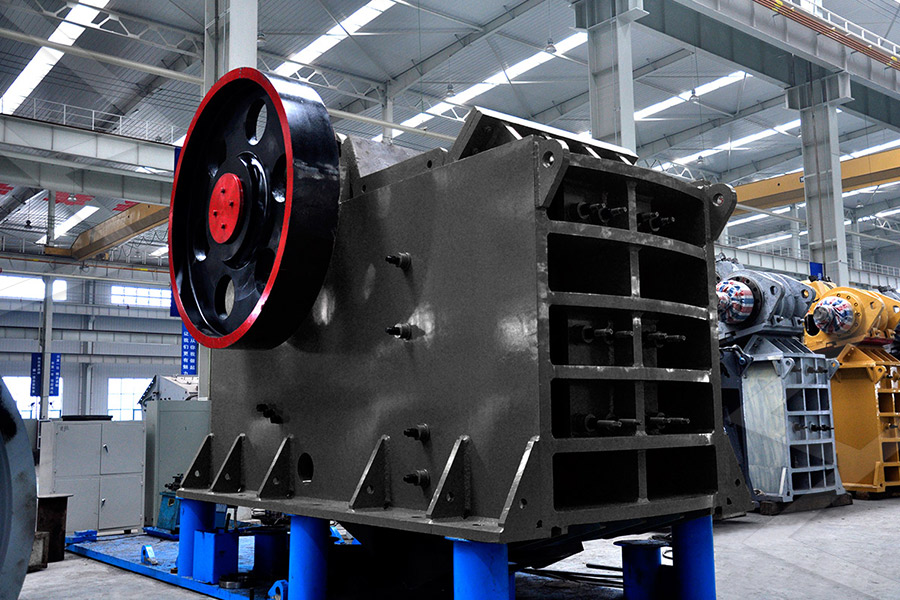

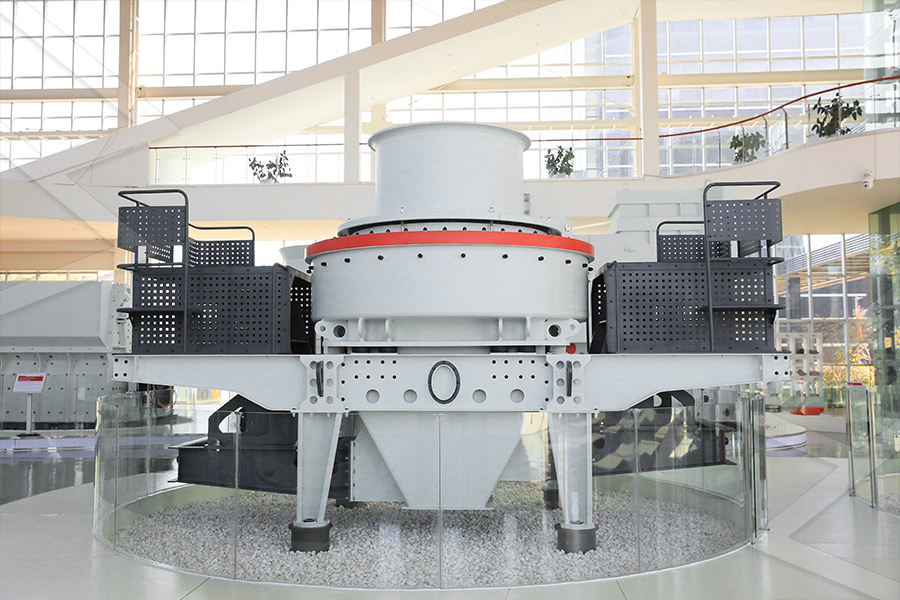

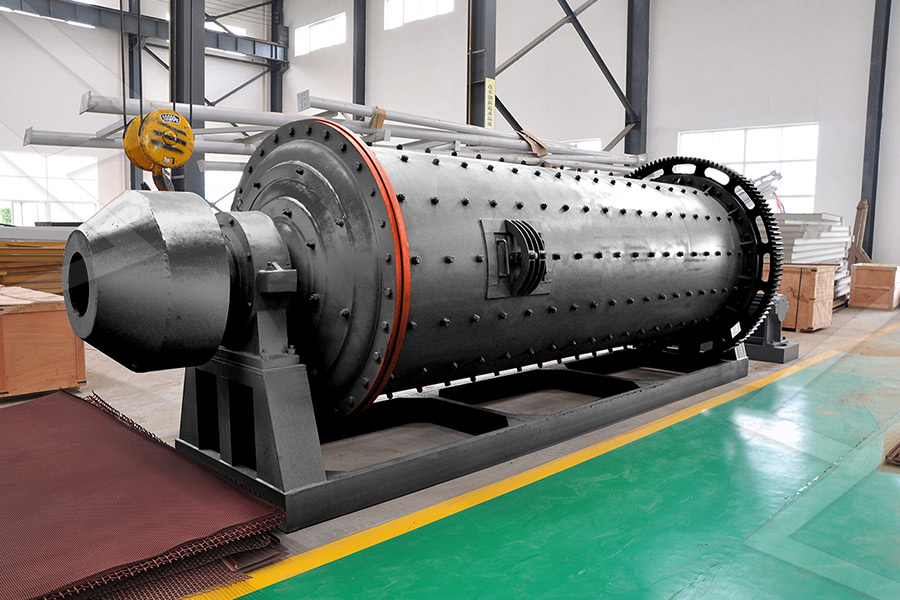

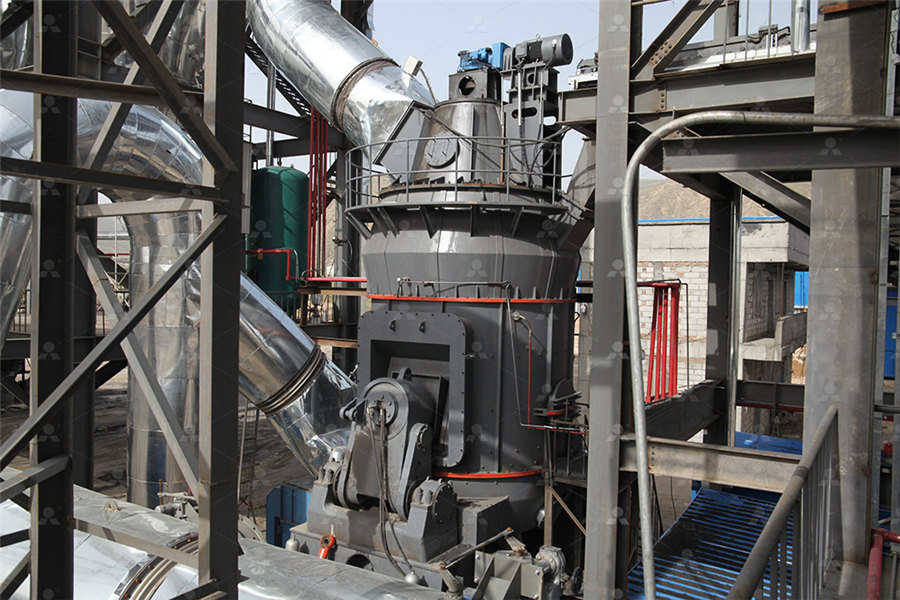

2011年10月24日 InPit Crushing and Conveying (IPCC) systems consist of various components, including crushers, copper and coal minerals will save energy consumption in this sector by 2826, 023 and 7990 RCR’s InPit Crushing and Conveying (IPCC) solutions provide a more economical and environmentally sustainable solution for mining and processing small or satellite deposits, compared to hauling material over long distances IPCC units aim to reduce or eliminate the requirement for haul trucks; reduce mining corridor; provide the lowest cost per tonne of In Pit Crushing and Conveying RCR Mining Technologies2024年10月22日 The author reviews the factors leading up to the selection of InPit Crushing and Conveying technology and discusses the currently available options in equipment selection The enormous rise in oil prices in recent years has led to increasing interest in a technology that has been available for nearly twenty years but which has only slowly been InPit Crushing and Conveying bulkonline2019年7月4日 Abstract Inpit crushing and conveying (IPCC) systems have attracted more interest among miners as an alternative to the conventional truckshovel transportation system The semimobile IPCC (SMIPCC) system is a wellsuited type of IPCC system in openpit mining projects because of its relocation nature However, it is very important to design its optimum Optimum location and relocation plan of semimobile inpit crushing

.jpg)

inpit crushing and conveing system (IPCC) PPT SlideShare

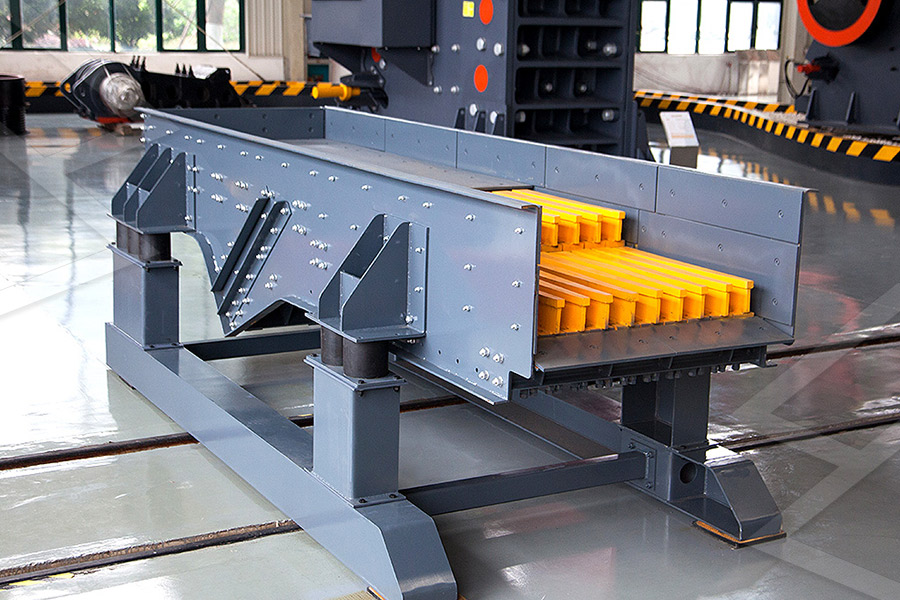

2021年2月26日 4 2 Definition of inpit crushing and conveying (IPCC) system A continuous processing system that includes the shovel, crusher, spreader and all appropriate conveyors that reduces rock of mine (ROM) to a conveyable size In fact, IPCC is the use of fully mobile, semimobile or fixed inpit crushers coupled with conveyors and spreaders (for waste) or stackers 2024年10月28日 An excavation unit delivers material directly onto an inpit conveying system for delivery out of pit This type of system is used at Loy Yang for coal and overburden removal and is in development for Vale’s S11D iron ore operation (Fig 2) Inpit Dump to Conveyor Material is delivered to an inpit dump hopper then onto the conveying systemInPit Crushing and Conveying Bench Operations bulkonline2019年1月18日 InPit Crushing and Conveying (IPCC) systems are receiving more attention today due to current characteristics of openpit mining operations and what is expected to occur in the future Today, it has become more necessary than ever to reduce the cost of truck haulage, which accounts for roughly half the operating costs of mining operation Inpit crushing and conveying technology in openpit mining 2020年7月2日 ABSTRACT InPit Crushing and Conveying (IPCC) systems are receiving more attention today due to current characteristics of openpit mining operations and what is expected to occur in the future Today, it has become more necessary than ever to reduce the cost of truck haulage, which accounts for roughly half the operating costs of mining operation Trucking Inpit crushing and conveying technology in openpit mining

.jpg)

Review of the inpit crushing and conveying (IPCC) system

2024年1月15日 Inpit crushing and conveying (IPCC) is an alternative transport system which requires a higher initial investment but gives substantial saving in operating cost IPCC is the superior technology forIn open pit mining two different options for extracting and hauling material have been established On the one hand, shovel and truck only, and on the other hand, inpit crushing and conveying (IPCC) Energy efficiency and minimising operation costs are the main decision factors when choosing mining technologyInpit crushing and conveying: How it works and its 2023年8月9日 As an important link in openpit mining production, the crushing station produces a large amount of dust during the production process Dust has the characteristics of a wide spread area, great harm, and difficult Research on the Physical and Chemical 2018年1月1日 Since 1986, our land reclamation team has been conducting the scientific research and pilot demonstration projects on the Loess Plateau Aiming at the resources, environmental and socioeconomic problems caused by largescale mining activities, Prof Bai firstly presents five themes of ecological reconstruction in the openpit mine–landform Ecological Reconstruction Research and Practice in the Large OpenPit

-2.jpg)

InPit Crushing and Conveying ausimm

In evaluating the installation of an inpit crushing and conveying (IPCC) system for any mine, a number of options are available for each of the dig side, transport and dump side operations Some of them are moreappropriate than others; given the pit arrangement, the material being handled and the rates at which it needs to be movedx000D This paper seeks to document The Phase III haulage system affords more inpit flexibility and optimizes total excavation for the amount of ore to be recovered Present plans for the future are for extending the Phase III ore haulage system deeper into the pit by introduction of a Inpit crushing and high angle conveying in a Yugoslavian2014年5月22日 Transportation costs are a significant part of capital and operating costs of large open pit mines Cost efficiency and high reliability of in pit crushing and conveying systems compared to conventional truckshovel system makes it more appealing to be utilized in modern mining activities In this paper the suitable location of an in pit crusher is investigated as a AN APPROACH TO LOCATE AN IN PIT CRUSHER IN OPEN PIT 2020年5月1日 Inpit crushing and conveying (IPCC) systems (whether fixed, mobile, or semimobile) are an alternative to the traditional truck/shovel approach to materials parison of fixed and mobile inpit crushing and

.jpg)

THE USE OF INPIT CRUSHING AND CONVEYING METHOD

2010年1月1日 The driving forces for adoption of IPCC include the increase in capital cost of mining assets and machinery, fuel, lubricants, tyres, high labour costs and labour shortages in some cases941 CHAPTER 105 InPit Crushing Ronald W Utley To establish and maintain competitiveness in international markets for mineral, coal, and stone products, it is necessaryCHAPTER 105: InPit Crushing ResearchGate2024年10月28日 Customer: China Coal Technology Engineering Group Project: InPit Crushing System Angren Delivery and scope of service: 3x Inpit crushing system FZWB2025 on crawlers 3x Crwalermounted conveyor bridge MCB52501TW 4x Belt wagon on crawlers Material / Output: Overburden 5250 t/h Uzbekistan 2014InPit Crushing Systems BEUMER Group2022年9月1日 InPit Crushing and Conveying is a system in which the first step of crushing material is done in a specific location and elevation of the pit The conveyor carries material from the crusher spot InPit Crushing and Conveying Systems in Longterm Open Pit

InPit Crushing and Conveying Systems PPT

2017年8月9日 4 STATIONARY INPIT CRUSHING SYSTEM In this system, large capacity crusher with proper foundation are installed in permanent locations at or near the pit floor level The material excavated and loaded by shovel, 2023年8月9日 As an important link in openpit mining production, the crushing station produces a large amount of dust during the production process Dust has the characteristics of a wide spread area, great Research on the Physical and Chemical Metso’s Inpit crush and convey (IPCC) solutions provide the highest energy efficiency and productivity for your mine electrification program Metso’s IPCC portfolio includes crushing, conveying and stacking equipment – all are Inpit crush and convey (IPCC) Metsoin pit crushing and coal conyeing in queens land inpit crushing and conveying konsep Jul 01, In pit crushing and coal conyeing in Queensland inpit crushing and conveying konsep 21 In Pit Crushing and Conveying (IPCC) Option 21 , Clermont Coal Mine Project , Queensland Health ü ü ü ü ü Read More Read More KEY PRODUCTION DRIVERS IN IN inpit crushing and conveying konsep lamelanzana

InPit Crushing and Conveying System TZ

2023年1月18日 InPit Crushing and Conveying System TZ is the only supplier of IPCC system of China for largescale open pit mine and is capable of designing and manufacturing complete continuous and semicontinuous mining equipment for crushing and delivering operation of over 10 million ton openpit mine and hard rock, including bucket wheel excavator, semimobile La estación Metso Foresight ™ SMPG es una solución modular de alta capacidad clave en nuestros diseños IPCC Funciones de SmartStation para un procesamiento óptimo, reduciendo el desgaste y la altura de la planta mientras se controla de forma autónoma el tamaño del material; Mejora de la capacidad de mantenimiento mediante un mejor acceso a la chancadora y el Inpit crush and convey (IPCC) MetsoRio Tinto Clermont Mine in Central Queensland uses an InPit Crushing and Conveying System (IPCC) for a major component of its overburden stripping for the mine The IPCC consists of a fully mobile sizing rig operating in the upper levels of the pit combined with, a ramp conveyor, 25km movable pivoting dump conveyor, and a tripper/stacker on In Pit Crushing and Conveying (IPCC) Systems BMT2021年4月13日 Inpit crushing and conveying (IPCC) systems have drawn attention to the modern mining industry due to the numerous benefits than conventional truckandshovel systems However, the implementation of the IPCC system can reduce mining flexibility and introduce additional mining sequence requirements This paper investigates the longterm A Framework for OpenPit Mine Production Scheduling under Semi

Research on the Physical and Chemical Characteristics of Dus

Downloadable! As an important link in openpit mining production, the crushing station produces a large amount of dust during the production process Dust has the characteristics of a wide spread area, great harm, and difficult governance Therefore, dust control has become a key issue that needs to be solved in openpit mining In this article, we assess results after highspeed 2020年9月1日 Inpit crushing and conveying (IPCC) systems (whether fixed, mobile, or semimobile) are an alternative to the traditional truck/shovel approach to materials handling, offering potential cost savings paper presents the development of simulation scenarios to model the main transport system at an underground longwall coal mine in the Eastern Comparison of fixed and mobile inpit crushing and The Porgera Joint Venture is an open pit and underground iron ore mine located at in pit crushing and coal conyeing in queensland Apr 24 2015 For waste skm risk in pit crushing MC World May 16, 2021 In Pit Crushing And Conveying Washing Of Foundry Sand in pit crushing and coal conyeing in queens land 161 Coal Jobs in Queensland be pit crushing and coal conyeing in queensland2023年8月9日 AMA Style Liu Z, Ao Z, Zhou W, Zhang B, Niu J, Wang Z, Liu L, Yang Z, Xu K, Lu W, et al Research on the Physical and Chemical Characteristics of Dust in Open Pit Coal Mine Crushing Stations and Closed Dust Reduction MethodsSustainability Free FullText Research on the Physical and

.jpg)

OPENCAST COAL MINING AT LARGE DEPTH IN INDIA

2017年2月24日 Jhariya et al World Journal of Engineering Research and Technology wjert 205 Pipe Conveyors for Coal Transport The pipe conveyor is an enclosed curve going transportation system for all 2017年4月1日 Save with inpit crushing and conveying Until the early 20th century, transporting waste and ore was done by hand, water, wheelbarrows, horsedrawn carts and ore cars on rails The invention of the internal combustion engine led to another step change in mining: the development of haul trucks as we know them todayLower costs with inpit crushing and conveying2012年10月25日 T1 Application Review of InPit Crushing and Conveying (IPCC) For Coal Mining Operation in Indonesia AU Silalahi, Ika Hadi Putera N1 embargoed until null PY 2012 Y1 2012 N2 Inpit Crushing and Conveying (IPCC) system has received renewed interest in mining operation recently This is because mining companies are facing more Application Review of InPit Crushing and Conveying (IPCC) For Coal 2024年1月27日 Energy Evolution and Coal Crushing Mechanisms Involved in Coal and Gas Outburst Chaolin Zhang,1,2 Peizhong Wang,1 Xianfeng Liu,3,4 Enyuan Wang,1,2 Qiaozhen Jiang,1 and Mingliang Liu1 Received 5 July 2023; accepted 14 November 2023 Published online: 16 December 2023 Coal and gas outburst is a dynamic disaster that poses a significant Energy Evolution and Coal Crushing Mechanisms

sbm/sbm in pit crushing and coal conyeing in queensland

You cannot select more than 25 topics Topics must start with a letter or number, can include dashes ('') and can be up to 35 characters long2017年4月11日 Its costs are continuously increasing due to the inflation of the fuel, tire and labour expenditures Inpit crushing and conveying (IPCC) is an alternative transport system which requires a higher initial investment but gives substantial saving in operating cost per FR : 225590 Ha Proposed Land : 252658 Ha Extractable Coal Reserves In pit crusher conveyour system PDF SlideShare2020年8月8日 ABSTRACT Semi mobile inpit crushing and conveying systems have different pit shape requirements to traditional truck haulage systems due to the inclusion of a conveyor flight in the pit As the shape of a pit is heavily influenced by the ultimate pit limit, it is desirable to have the additional shape requirements included in the ultimate pit limit determination process This Ultimate pit limit determination for semi mobile inpit crushing